Garlic (Allium sativum) is a plant primarily used as a condiment or seasoning and found in a wide variety of food applications. Used in many Mediterranean cuisines, it now finds use in foods around the world. It has a characteristic flavor that will vary depending on whether the product is fresh, dehydrated, cooked or in oil form, as well as on the variety and growing conditions.

China produces most of the world’s garlic, where it is planted in spring and harvested in late autumn. The three major forms of garlic are: Fresh garlic, dehydrated garlic and garlic oil. China exports the most garlic—increasing 3.75% a year since 2006—but internal consumption has been growing as well at 1.2% annually. About 80% of total Chinese production is in the form of fresh garlic. The second largest volume of garlic is dehydrated garlic, and exports of dehydrated garlic from China have been growing at over 2% annually since 2006.

For flavor chemists, garlic oil is probably the most convenient form. It is highly concentrated and, as an oil, it can be blended into top notes, emulsified to be water dispersible or spray dried into a powder. It is expensive, as one metric ton of fresh garlic produces only 2.5 kilograms of oil. Once again, China produces the most garlic oil with small amounts made in India and Egypt. Production tends to start in October or November, after the fresh garlic crop has been allocated and the balance available is for powder (dehydrated) and oil production. Global demand has been steady or slightly decreasing at about 80 to 100 metric tons a year. However, supply of oil has been tight. Consumers, globally and in China, have been demanding more fresh garlic, which leaves less for oil production, resulting in a shortage. Technology to store fresh garlic allows China to hold fresh garlic for up to two years rather than process it as oil. The Chinese government has been strictly enforcing environmental regulations, which impacts the waste disposal and the air pollution (garlic oil production is known for its stench). The garlic oil flow chart (see F-1) demonstrates the challenges of solid waste and waste water.

Adulteration Concerns

All these factors have led to garlic oil increasing in price, 200% in the past year alone (see F-2). Due to its concentrated form, easy to disperse in oil matrices or plated and/or spray dried onto carrier, garlic oil remains very popular for savory flavor chemists. Most flavorists want to use natural flavorings. But with tight supply and skyrocketing prices, procurement departments will start looking for new suppliers. Unfortunately, the other vendors also fall short of this and will want to take care of their traditional customers first. So, procurement teams look at vendors they have not had experience with and the opportunity arises for adulteration.

Adulteration can be in the form of a natural flavor with natural but non-garlic flavor components. Technically, this is a natural garlic flavor with other natural flavors (WONF). Otherwise, the product may be substantially or completely synthetic, made from petroleum-derived ingredients, in which case it is an artificial garlic oil. In either case, the vendor may offer a natural certificate and the specification sheet will say their product is 100% natural garlic oil. So, since a large percentage of the available garlic oil on the markets may be adulterated, how can a company detect adulterated garlic oil?

Strategic Detection: Synthetic vs. Natural

Amid the large body of scientific literature published on the topic, two recent articles highlighted strategies for detecting synthetic compounds in complex samples. Lambert et al. showed how chiral analysis is able to assist in determining the natural enantiomeric ratios of flavors [1]. In November 2016, Saint-Lary et al. presented a detailed description of some of the techniques available to help authenticate natural materials [2]. Among the list of options available to the analytical chemist, radionuclear testing (e.g. 14C, 13C, 2H) is one the most widely used technique to determine the presence of fossil fuel derived material (i.e., synthetic) in essential oils. However, it is an expensive, multi-step and labor intensive process, limited to a few expert laboratories. On the other end of the spectrum, gas chromatography with flame ionization detection (GC-FID) is now an established routine technology in most flavor companies. Therefore, early on, using chemometric tools, we decided to combine the information obtained from 14C analysis and GC-FID for Chinese garlic essential oil. Ultimately, a GC-FID predictive model of synthetic adulteration in garlic oil was developed using multiple linear regression (MLR) [3].

Garlic Oil Volatile Compounds

Garlic essential oil is mostly comprised of sulfide volatile compounds (see F-3 through F-6), e.g. diallyl disulfide (DD), allyl methyl trisulfide (AMT), diallyl trisulfide (DT) and diallyl tetrasulfide (DTT). In F-7, GC-FID chromatograms of natural vs. synthetically adulterated garlic oils are presented. It should be noted that when compared to natural garlic oil (see F-7A), adulterated garlic oils with varying levels of synthetic adulteration (see F-7B through F-7D) will have some differences in their GC-FID volatile composition. While some of these can be easily spotted with one’s naked eye (e.g., higher levels of DD with higher synthetic content), other more subtle differences are more difficult to identify, especially at lower adulteration content. When analyzing dozens of samples, a simple visual check of a GC-FID chromatogram is neither practical nor objective enough to accomplish both the detection of adulterated garlic oil and the quantitation of adulteration. Therefore, we opted to have the data processed by chemometrics in order to find some patterns, develop a model and then build an equation to predict the level of adulteration in garlic essential oils. This entire project was accomplished using garlic oils of Chinese origin.

Principal Component Analysis

The first step in chemometrics involved principal component analysis (PCA) where the raw data (in this case, GC-FID peaks) is processed mathematically, resulting in a scores plot (see F-8) where individual samples are grouped or clustered based on a reference measurement (in this case, level of synthetic adulteration as determined by 14C analysis). Using 12 garlic oils with different levels of synthetic adulteration ranging from 0% to 27%, the PCA scores plot easily separates the natural samples from the synthetic ones. Further, 99% of the dataset is explained using only two principal components (PC), with PC1 accounting for 67% of the data and PC2 for 32%. Further review of the PCA results (with loadings plot) highlighted the following volatile compounds as the three major contributors to the grouping observed in F-8: DD, AMT and DTT. It should be noted that DT was the fourth PCA contributor, but we opted not to include it as further work showed it was not a required predictor in the final MLR model.

Multiple Linear Regression Model

Based on the earlier PCA results, GC-FID peak areas for DD, AMT and DTT were used to develop an MLR model. However, in order to remove any variability in peak areas that might arise from instrumental or sampling issues—just to name a few—we decided to input selected area ratios of these peaks, making sure that the resulting ratios were not cross-correlated. Therefore, we ended up using the following independent peak area ratios as MLR predictors in the model: DD/AMT, DD/DTT and AMT/DTT. The MLR criterion was the percent synthetic in the oil as determined by 14C analysis.

While we had several samples with synthetic content higher than 60%—with some at 100% synthetic—we decided to exclude these from the MLR model, as these higher values were negatively affecting the model by skewing the resulting predictive equation. Therefore, the MLR model (see F-9) was built with samples ranging from 0% to 30% synthetic as determined by 14C analysis (x-axis in F-9). The predicted percent synthetic content in garlic oil (y-axis in F-9) can be calculated using the following equation:

Testing the Model

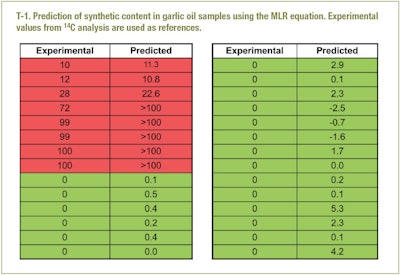

The predictive equation that resulted from the MLR analysis was then validated using 28 new garlic oil samples, i.e. samples that were not used in the modeling phase of the project (see T-1). Of these, eight samples were confirmed through 14C analysis to contain some levels of synthetic compounds. The remaining 20 samples were shown to be devoid of any fossil fuel derived material.

The predictive equation was able to properly identify all the authentic and adulterated garlic oils, without any false positive and without any false negative results, thus providing a cheap and easy screening tool to authenticate natural garlic oils.

Challenges Ahead

While the predictive model is working quite well, some challenges need to be addressed. First, with the wider adoption of new analytical assays designed to catch adulteration, adulterators, who might also be skilled chemists, are becoming increasingly more ingenious and entrepreneurial in trying to circumvent these new detection methods. For instance, in order to fool the outcome of the 14C test, someone with access to 14C radiolabeled material could potentially boost the 14C content of a garlic oil sample to a level closer to authentic garlic oil (i.e., 0% synthetic). However, with a secondary screening test such as the MLR predictive model based on GC-FID chromatograms, the analytical chemist has yet another tool available to detect adulteration. In this respect, the GC-FID approach is an orthogonal option to the 14C test, making these two assays complementary.

As we just discussed, with ever more clever adulterators, the model might have to include additional volatile compounds in the MLR model, in order to make the GC-FID test more rugged. From the PCA work described earlier, an updated model would likely have to include DT as a fourth compound.

Finally, since China is the largest producer of garlic oil, this model was developed and validated using Chinese garlic oils. For garlic oils from other regions such as Egypt, new region-specific predictive models would need to be developed.

Conclusion

You need to know what you are paying for. Is it 100% natural garlic oil? Is it a “WONF” and not all from the named source? Is it actually a misbranded synthetic product? Paperwork and certificates are no substitute for working with trusted suppliers. If you have to seek out new suppliers, you will need to spend the money to verify the nature of the garlic oil you are purchasing.

Acknowledgements

The authors would like to thank Maria-Paz Gonzales of Kalsec, Inc. for the statistics and market data, and Jane Guido for structure drawings.