Humans are always looking ahead to the next innovation, the next bit of technology that will help make lives easier, and that is certainly true in the flavor and fragrance industries. Automation technologies are being developed for various tasks considered mundane and time-consuming, and research is always evolving in this space.

Perfumer & Flavorist+ enlisted the help of Rich DiBernardo, CEO of iniTech Inc; Masoud Bahmai, managing director at Accurate Dosing Systems; Heli Kilpala, strategic marketing and innovation director at Biospringer by Lesaffre; and Antoine Thomas, flavor development manager at Biospringer by Lesaffre to share how they believe artificial intelligence and automation will influence the flavor and fragrance industries.

How do you see the role of artificial intelligence in the flavor and fragrance industry evolving over the next year?

Rich DiBernardo, CEO of iniTech Inc.Courtesy of Rich DiBernardo

Rich DiBernardo, CEO of iniTech Inc.Courtesy of Rich DiBernardo

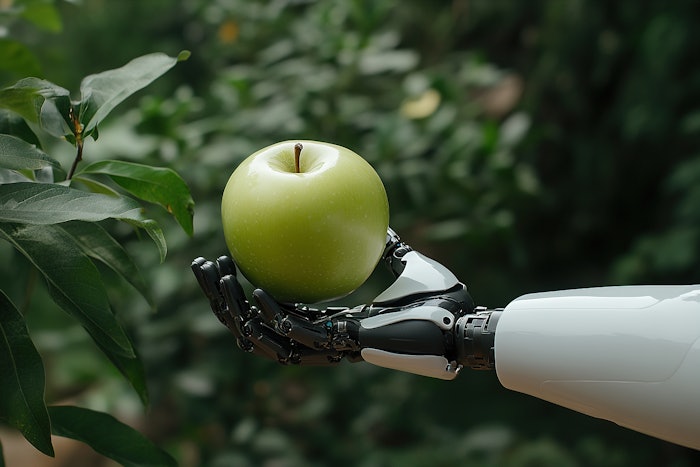

Masoud Bahmai [MB]: AI has the potential to significantly disrupt the flavor and fragrance market in the coming years. Robotic-dosing systems will assist the AI-driven software in creating and evaluating samples. This will require very fast dosing robots capable of producing thousands of small-scale samples daily, combined with AI software equipped with advanced sensors that can "sniff" and learn to refine formulations continuously.

Heli Kilpala and Antoine Thomas [HK, AT]: Artificial intelligence has been cited as a new solution to accelerate creation and enable the emergence of more competitive new products on the market for a few years now. In my opinion, there are two major points I would like to develop.

First, the ability to generate data, because without data there is no AI. In our industry, this means collecting a large amount of data at every stage of a product: data on raw materials, processes, analytical compositions, sensory evaluations, and properties. All this data generation and collection is starting to be well implemented by the largest players in the industry (the larger the company, the more data it has, which can give a crucial advantage to big players).

And second, the ability to analyze this data and put it at the service of the business. Digital & Data teams have become strategic for these companies that want to be the pioneers of AI in the F&F industry, and it is these specialists and the strategy of putting them at the center of interactions with the business that will enable this emergence and acceleration in the market.  Heli Kilpala, strategic marketing and innovation director at Biospringer by LesaffreCourtesy of Biospringer by Lesaffre

Heli Kilpala, strategic marketing and innovation director at Biospringer by LesaffreCourtesy of Biospringer by Lesaffre

Many solutions are already being implemented internally, and are already helping to facilitate the work of certain teams (literature searches, quick analysis of large datasets to uncover trends, insights, or patterns, etc.). We see that AI is there to work next to humans, enhancing productivity, efficiency, and decision-making in daily work tasks across the industry.

How can robotics and automation help the flavor and fragrance industry while keeping that “human touch”?

[RD]: In flavor and fragrance manufacturing, automation has already replaced some of the repetitive, manual operations on the shop floor, improving efficiency, precision, and consistency. Before PLC-based automation (programmable logic controller), operators manually measured, weighed and dispensed all ingredients, leading to batch inconsistencies, human error and physical strain from handling heavy materials. PLCs now control ingredient dispensing systems, ensuring precision and eliminating some of the manual measuring. Instead of eliminating jobs, PLCs create a demand for technicians and programmers, to program and troubleshoot automated systems, and process analysts, to oversee decision-making and continuous improvement.

Now, as AI and humanoid robots are introduced, I believe that they will follow the same pattern as PLC-based automation—not replacing workers but supporting them in areas where hiring is increasingly difficult. As AI becomes more integrated with manual work processes and shop floor automation, humanoid robots will soon be providing “workers” to fill labor gaps where human workers are becoming harder to find.

Just as PLC-based automation created higher-skilled jobs, I believe that AI and humanoid robots will do the same—enhancing efficiency, reducing strain, and enabling innovation. The real challenge isn’t job loss but upskilling workers for an AI-driven future while automation fills roles people no longer want.

Masoud Bahmai, managing director at Accurate Dosing SystemsCourtesy of Masoud Mahmai

Masoud Bahmai, managing director at Accurate Dosing SystemsCourtesy of Masoud Mahmai

[HK, AT]: As is often the case when talking about AI, I think it needs to be seen as a tool to serve the creative teams, rather than as a replacement for humans tomorrow. The first ones mentioned are the formulators (perfumers and flavorists), who will retain that precious creative role that makes the difference for the client. On the other hand, AI tools will make it possible to accelerate and facilitate their work, for example by pre-selecting certain formulas or raw materials to test, providing tracks of reflection to explore, and above all by carrying out a large number of trials upstream of the human's work. This technology is a tool at the service of the human, who remains the master of the initial brief and the final validation of the product.

Antoine Thomas, flavor development manager at Biospringer by Lesaffre.Courtesy of Antoine Thomas

Antoine Thomas, flavor development manager at Biospringer by Lesaffre.Courtesy of Antoine Thomas