Citrus oils are among the most popular natural raw materials in flavor and fragrance-driven consumer goods. Carbonates, fruit and chewing gums, beer mixes, toothpastes, perfumes, household cleaners and many others partially depend on the by-products of citrus juice processing. These consumer goods can be found in millions of homes worldwide, and their popularity even increases thanks to Africa and Asia’s strongly growing emerging middle classes. Overall, it is a good time for citrus processors who want to sell their peel oils to meet growing global demand – or is it?

A Challenging Raw Material Market

However, the citrus market does not look as bright when you consider the supply side. Running a profitable citrus processing business has become much harder in recent years. Climate instability is taking its toll all over the world, from floods, droughts, frost, hurricanes or other natural disasters occurring more frequently, while the negative impact on citrus harvests and global fruit availability intensify. All of these factors hardly reach the magnitude of the biggest threat to the citrus industry, though: the disease known as citrus greening or HLB. Its devastating effect on Florida was just the beginning. Traditional citrus regions like Mexico, Brazil and China all report similar incidents: trees infected, fruits dropping, harvests lost – and no cure in sight. Current discussions to focus on resistant tree varieties which are based on genetically modified organisms (GMO) only wait for the backlash from NGOs which want to ban GMOs, especially from consumers’ foods and drinks. It is only understandable that some farmers give up under these circumstances and shift to other “easier” cash crops like sugar cane.

Yet while the amount of fruit is affected by these factors, the demand for fresh fruits is as high as always – thus processors have to compete for their fruits with traders and supermarkets, leading to price increases. In the “good ol’ days” this was hardly a problem especially for the Western world which was thirsty for juices and nectars. This demand is sharply declining, though, as consumers shift their preferences to less caloric beverages – the traditional hook of the natural “health drink” has lost its grip. Thus, processors face two problems simultaneously: decreasing supply of fruit and decreasing demand for its major derivative, the juice. The strongly growing demand for peel oils, traditionally a less relevant by-product of fruit processing only, cannot compensate for the potential loss of income from the juice side. The result is a widening global gap between citrus peel oil supply and demand.

Bridging the Gap with Alternative Natural Sources

It has been the heritage of the flavor and fragrance industry to offer solutions for this dilemma: not everything which tastes or smells like citrus needs to be derived from citrus sources – synthesized artificial aroma molecules most often could do the job. With an ever growing demand for naturalness, though, this traditional route is no longer feasible. Instead, producers look for botanical alternatives which contain building blocks for citrus taste and smell. Aromatic herbs and spices are fractionated to isolate citrus notes: citral from Litsea cubeba, linalool from rosewood oil and complex citrus tastes from lemongrass are among many other widely used botanical extracts. While these extracts may not face the same issues as citrus fruits, their use hardly offers significant relief from sourcing issues, nor does their cost in use turn the needle to make them widely applicable. They have their benefits – but miracles are not to be expected.

Instead, one way to generate new citrus building blocks is to revisit the initial process of fruit extraction, with the objective to generate value from waste. Even the most efficient fruit processing operation not only yields high-value main products but also includes various side and waste streams. Parts of these can be commercialized like crushed fruits and peels, first being stripped of pectin and then given to farmers as animal feed. Yet in these materials, there can still be a lot of hidden value, something that can be released using innovative extraction technologies and supply chains.

The industry’s biggest hope, however, might not come from botanical alternatives or more efficient extraction. It could instead be a “return to the roots”: synthesis of aroma chemicals and flavoring preparations – but in an all-natural way. The traditional synthesis logic still applies here: different starting materials are transformed into new interesting compounds or blends. What was previously mainly based on petro chemistry now has to work in a natural way, though, with natural starting materials going through natural processes to result in natural flavoring preparations. As legal demands on the processes to remain natural are strict, this has led to reviving kitchen-like principles – but now obviously in a sophisticated high tech way.

Creating Natural Taste and Scent Building Blocks

Natural transformation is the key to new natural raw materials in the future, using both citrus by-products and other natural starting materials. Whether very basic “cooking” methods or modern biotechnology are applied, the spectrum of possibilities is huge. Relatively easily sourced valencene from oranges can be transformed to replace nootkatone from grapefruit, which is getting harder and harder to find. Natural linalool will react with natural acetic acid to form natural linalyl acetate. Natural fatty acids can be converted via enzymes and air exposure to natural aldehydes. The list of examples could be almost endlessly expanded. They all represent a more sustainable way of using the natural principles of fermentation and enzymatic kinetics to generate valuable taste and scent solutions.

Natural processes hardly ever work in isolation, though. Physical separation technology remains a key enabler and is often applied complementarily. The goal is to extract or to enrich the desired material, and to remove the (sensory-wise) undesired part. From basic vacuum to short path/molecular distillation, via solvent extraction, adsorption/desorption and chromatography, up to high-end membrane separation, many different technologies are commonly used. The real “art” lies in the right selection of natural starting materials with reliable sourcing access, the application of value-maximizing technologies, and their smart combination to get the desired outcome: natural building blocks for superior citrus oil alternatives.

Citrus Oil Alternatives – Refreshingly Different

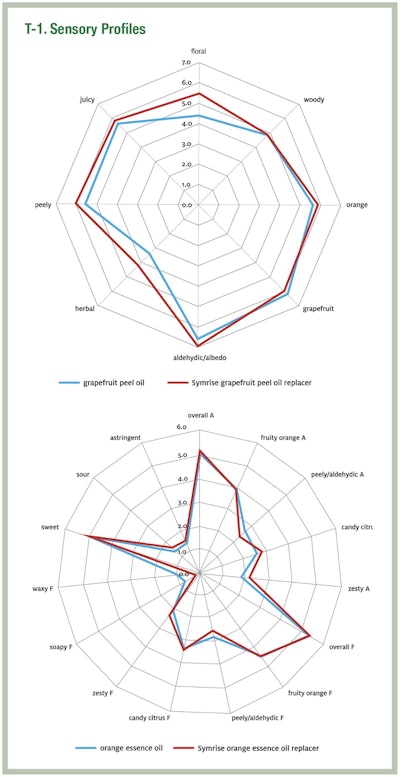

Mother Nature has always been the benchmark for new flavor and fragrance developments, and so it is with citrus oil alternatives. By decoding the sensory and analytical profiles of natural citrus oils, the objective seems obvious: recompose these profiles using raw materials from other natural sources. Great progress has been made in achieving this natural citrus to non-citrus match (see T-1). Only copying these would be wasting potential, though: citrus oils come with various inherent challenges which can be already addressed when developing effective countertypes.

The biggest benefit to realize with citrus oil alternatives is obviously securing future supply. More exotic citrus varieties are within reach, as their taste and smell composition can be based on mainstream varieties and other natural sources. What was previously mainly relevant for “niche” fruits like yuzu or calamansi now takes on another dimension by including once widely available citrus products like white grapefruit peel oil or essence oils of orange and grapefruit. The focus here shifts from affordability to availability, from being forced to pay a very high price to an inability to obtain the material regardless of the willingness to pay a premium - or even a fortune!

Meanwhile, affordability is still the determining factor, of course. As processing volumes drop further, prices for specialty by-products will continue to sharply increase, while effectively becoming too expensive to meet the limited cost in use targets in fast moving consumer goods. Citrus oil alternatives can offer a partial relief here as they might be formulated in cost-effective ways which reflect today’s natural citrus oil prices, thus offering a reliable scenario for the near future with reasonable price stability versus citrus oil prices that are likely to continue increasing.

Reducing future cost pressure and getting safer supply are the mandatory basics for citrus oil alternatives, yet there are various opportunities beyond that. Designing smarter constraints, various challenges of natural citrus can be prevented. An easy one is standardization: creation of the formula from scratch can overcome the variations naturally found in citrus raw materials because of harvest fluctuations and provenance. It can also by-pass one of the least welcome yet common problems of citrus: agricultural residues. By not using natural citrus materials, the risk of elevated pesticide levels is mitigated.

The benefits of citrus oil alternatives are complemented by enabling fit-for-purpose raw material creation. Naturally occurring negative characteristics of citrus oils do not require difficult removal but can be avoided from the beginning: absent phototoxic furocoumarins enable use in perfumes and cosmetics, controlled levels of terpenes increase solubility in beverages and customized levels of critical ingredients like citral allow improved aroma stability in selected target applications.

These, among other benefits, are the rationale to create more citrus oil alternatives in order to overcome the supply gap of natural citrus oils. But these alternatives do not come without their own challenges, of course. The biggest hurdle to overcome is natural complexity and authenticity. Reducing complex natural raw materials like citrus oils with their hundreds of aroma chemicals in widely different concentrations to a selected few in a lab are likely to feel “empty” and incomplete. Nature’s beauty is especially evident in its complexity, reflected both in the aroma profile and in its release. And beyond the volatile there is the nonvolatile level it needs to compare to, with mouthfeel being the biggest challenge to master. Meanwhile, various options to close the sensory gaps exist thanks to continued flavor research in reduced-calorie foods and drinks. Some of the solutions developed for low or no sugar taste solutions complement the citrus oil alternatives to come close enough to the natural citrus oils’ sensory target.

A Look into the Near Future

Currently, there is still no need for 100% non-citrus ingredients in citrus taste solutions. Since natural citrus materials are still available, it’s unnecessary for these materials to be completely replaced. Besides the commercial aspects, there is also the consumer preference element which calls for natural citrus. Even while being unaware of the greater picture of peel oil’s supply and demand, consumers are willing to pay more for natural citrus-derived taste and odor solutions – within reasonable limits. And as nature’s complexity is hard to match completely, blending natural citrus with alternatives is the most sustainable and effective way forward anyway. Some citrus specialties might need earlier replacement than others, though. Thus having citrus oil alternatives ready and established can already take pressure off the sensitive supply chains and make the industry master the challenges to become fit for the future.