Overview of Agarwood

Agarwood is the resinous wood of a tree from Aquilaria and Gyrinops species, which is highly prized as a premium raw material used in fragrances and traditional medicines. The trees naturally grow in the forests of Southeast Asia (SEA), primarily distributed in countries namely India, Malaysia, Bhutan, Thailand, Vietnam, Cambodia and Sri Lanka. The history of agarwood stretches back to ancient times and its use has largely been associated with regional, cultural and religious beliefs. Agarwood is also considered as sacred. Due to its extremely high value, the species has been hunted down from its natural habitat in the forests, reducing its availability at an alarming rate. The two species are now considered endangered and have been listed in Appendix II of the Convention on International Trade of Endangered Species (CITES) of Wild Fauna and Flora. Enforcement of CITES on agarwood put the activities of exporting and importing agarwood from the wild under very stringent control.

Ajmal has been on the forefront to engage with CITES and other entities to draft a regulation for differentiating between wild and harvested agarwood trees – paving the way to commercial harvesting by farmers for sustainability as well as to simplify rules and regulations. Today, millions of agarwood trees have been planted primarily in North East India by farmers with the help of AJMAL (see F-1). Agarwood plantations not only promise a sustainable supply of agarwood and its derivatives to the market but also help in conserving the near-extinct Aquilaria and Gyrinops species. It also generates employment and small business opportunities for people living in rural areas. Thailand, Cambodia, Malaysia and Vietnam are promoting and encouraging plantation of agarwood trees. The number of agarwood trees planted in all its producing countries has increased in recent years due to awareness regarding the potential demand of agarwood among the industry players.

Aquilaria malaccensis, or synonymously known as A. agallocha (understood as such from hereon), A. crassna and A. sinensis are among the most common species of Aquilaria cultivated in plantations. A. malaccensis is primarily planted in India and Malaysia, while A. crassna grows well in Cambodia, Thailand and Vietnam and A. sinensis in China. Other species of agarwood producing tree are still probably used but are decreasing due to non-favorable harvesting conditions. Interestingly, the same species grown in different countries gives off different aromatic profiles, possibly due to external factors such as soil and climate. Different aroma has different value and therefore, appeals differently from one individual or region to another. This is also probably why the market prefers to distinguish the different types of agarwood according to their country of origin rather than the species. Among the most common nomenclatures used in the market to classify agarwood are Hindi, Malaysian, Cambodi, Trat and Indonesian. Agarwood oil originating from Assam in India is preferred by perfumers and is the first choice. We arrived at this conclusion on the basis of inviting top perfumers in the world to Assam and together evaluating all the commercial varieties of agarwood oil available in the market. Prices can vary according to individual preferences and suitability in required applications.

These days the use of agarwood oil in perfumery is preferred to create new directions/notes in perfumery for a novelty in various products – but high price and sustainability is still an issue. This project needs active support from government entities and has huge potential of rural job creation. Currently, the supply of agarwood is only 40% of the market demand with a total global export of agarwood oil recorded in 2012 amounting to 4,870L.1-2 There is remarkable shortage in supply of agarwood compared to its demand in the market. Continuous worldwide agarwood replanting initiatives by industry players like Ajmal and others – via professional management and planning approaches – promise to overcome the shortages in supply and potentially expand and diversify the market for agarwood in the near future.

Evolution in global economic landscapes as well as other localized factors have either directly or indirectly revolutionized the way agarwood is used in the current era, compared to how it was in the past. While its primary use as incense, essential oil, perfumery and as a medicinal ingredient has remained almost unchanged compared to the past; the processes used – as well as the methods of delivering the products to the market have remarkably changed. The changes include expansion in the range of perfumery products offered according to the changing trends in fragrance industries and introduction of agarwood into unconventional markets such as cosmetics, skin care and household products. As a medicinal ingredient, agarwood can be processed into various forms as allowable by the current technologies developed for medicinal products. The only thing that remains the same is its use in religious rituals or get-together events that are closely associated with traditional culture.

Species of Agarwood

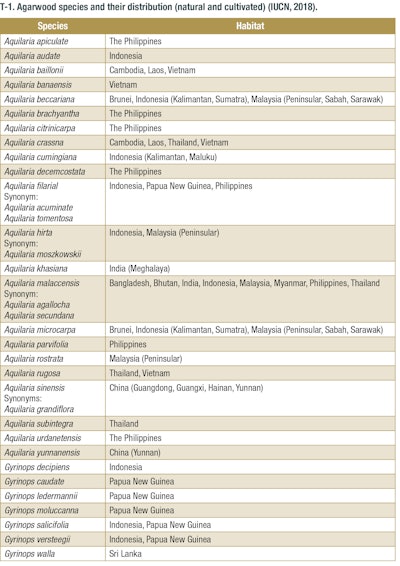

Aquilaria and Gyrinops are the two genius belonging to the family of Thymelaeaceae, which is frequently associated with the formation of agarwood. There are at least 29 species of these genera that have been officially recorded worldwide as presented in T-1. The species are native to Southeast Asia (SEA) and found heavily distributed in the forest of India, Malaysia, Burma, China, Cambodia, Thailand, Indonesia, the Philippines, Papua New Guinea and Sri Lanka. Aquilaria populates a wide range of areas such as the rocky, sandy, calcareous, well-drained slopes and ridges and swamps. The tree typically grows in area of altitudes between 0m-850 m, with average daily temperatures of 20-22°C. However, only a few of these species reportedly produce agarwood and its formation in the wild is extremely rare, probability only approximately 7% to 10%. Overexploitation of the species from its natural habitat has further reduced this number, pushing them close to extinction.

Morphologically, the two genus are differentiated based on the number of stamen. While the number of stamen in Aquilaria is twice the number of its petals, Gyrinops has equal number of stamens and petals (see F-2). Further differentiation among the species within the same genus based on morphological studies alone is even more difficult. The trees typically have pale grey fibrous bark with the leaves spirally arranged, unparalleled to each other. They grow slowly and their height varies between 15m and 60 m. In the past, specimens of a particular species are deposited in various museums in order to compile morphological data for species identification. Advancement in DNA sequencing technology enables a highly accurate approach for species identification at molecular level and thus, supports the findings made via morphological studies. Out of these species, A. malaccensis, A. crassna and recently, A. filaria are identified as the most important sources of agarwood; of which the first two species are the most commonly cultivated in plantation.

Anatomy of Aquilaria spp.

Microscopic studies on the anatomy of Aquilaria spp. is important particularly for identity validation and quality assessment (see F-3). Generally, most of the wood characteristics are conserved within the same genus and thus, facilitate identification and differentiation of the wood at genus level. There have been many reports on attempt to sell counterfeits made of ordinary woods that are treated with chemical solution as agarwood.3 Some of them were only captured after microscopic investigations were carried out by professionals. Compared to other angiosperm, Aquilaria tree has peculiar trait such as the growth of phloem throughout the xylem known as ‘included phloem’ and in the layer external to the xylem.

The phloem appeared as scattered islands under microscopic observation of the traverse sections of the wood.4 These ‘included phloem’ may have formed inwardly as a result of cell differentiation in cambium to close the wound, following plant injury. F-4 shows the unique internal morphology of A. malaccensis grown in Malaysia. The resin appears as black patches in included phloem, parenchyma cells and xylem of the wood indicating the significance of these plant structures in depositing and distributing the resin.5 Parenchyma cells may have active role in formation and secretion of resin and included phloem may have involved in distribution of the resin. These dark patches are not observed in healthy Aquilaria wood or other woods disguised as agarwood through a particular treatment.

Formation of Agarwood

Agarwood is known as the pathological product produced by the tree as a result of its defense mechanism against external threats. The process is part of the plant evolution to provide physical and/or chemical barriers that protects the plant from pathogen invasion before or after tissue wounding.6 A healthy Aquilaria tree is typically white or pale yellow, which is practically devoid of any resin and therefore, lacks the singular odor that defines agarwood. As a healthy tree, it is almost valueless as fragrance material and almost unsaleable in the market. On the other hand, agarwood refers to the dark resin formed in the stem, branch or root of Aquilaria and Gyrinops trees, following the wounding of the tissue and infection by particular fungal species and by other mechanisms. In their natural habitat, the wounding could occur due to strong wind, lightning strikes or the gnawing of ants or insects triggering the defense mechanism.

Generally, the plant’s defense mechanisms involve activation of biosynthetic pathways for production of secondary metabolites, primarily from sesquiterpene group. They are produced via activation of enzymes known as sesquiterpene synthases that controls mevalonate pathway. These secondary metabolites are deposited around affected tissues to form an occlusive barrier to prevent further spread of microbial invasion. Accumulation of these secondary metabolites forms the resin, otherwise known as agarwood. However, formation of agarwood in the wild is usually a time-consuming process that could take 20-50 years to fully develop (see F-5). Usually, trees of around 40-50 years old would contain fully-developed black patches in the trunk, particularly at the junctions where branches formed from the main stem. In some cases, the tree can recover by growing healthy tissues, shutting down the defense mechanism and the related biosynthetic pathways associated with production of secondary metabolites that form agarwood (see F-6).

Various efforts have been made to mimic the natural occurrence in the wild to trigger formation of agarwood in plantations (see F-7). The process is known as artificial induction or inoculation depending on the methods used, which include nailing the trees or treating them with solutions containing chemicals or fungal strain. Shortly, formation of agarwood can be initiated by triggering the plant defense mechanisms using physical, chemical or biological methods that can put the tree under significant stress. Some species tends to develop the resin faster than the others and the duration can vary depending on the area of cultivation. However, it is important to note that depending on individual business models, the longer the duration for formation of agarwood, the longer it takes to make return on investments; threatening the feasibility of the business. Over the years, various techniques of inoculation have been refined, screened and validated to improve the efficiency.

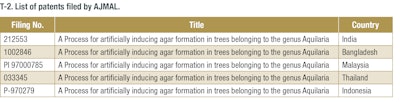

Ajmal has been pioneering the plantation of agarwood and development of inoculation techniques to artificially induce agarwood formation. The company was the first to file a patent on a technology developed for induction process in 1994. Currently, there are a total of five patents which have been registered or filed by Ajmal regarding their in-house agarwood inoculation processes. The patents are summarized in T-2.

Marker Compounds of Agarwood

Agarwood is mainly composed of sesquiterpenoids, which are primarily derived from groups of sesquiterpenes namely agarofuran, agarospirane/vetispirane, cadinane, eremophilane/valencane, eudesmane/selinane, guaiane, prezizane and nootkatane (see F-8). Sesquiterpene is part of terpene family, which is the largest class of hydrocarbon. Terpene is made of basic isoprene unit of C5H8. Sub-classes of terpene namely monoterpene, sesquiterpene and diterpene are made of two (C10H16), three (C15H24) and four (C20H32) isoprene units, respectively. Analysis using gas chromatography mass spectrometry (GC-MS) has shown that composition of sesquiterpene derivatives may be different depending on the specimen types, species or origin of the raw materials used and the treatment that specimen had subjected to prior to extraction process. Reconstruction of the olfactory profile of agarwood is extremely difficult as it is a mixture of sesquiterpenes that are originally produced by the tree and derivatives formed from decomposition of sesquiterpenes or from heating reaction.

Currently, there are more than 70 sesquiterpenes reportedly found in the essential oil of agarwood. The research on chemical composition of agarwood has been rigorously conducted for more than 40 years and among the earliest compounds reportedly found in agarwood oil was agarol.7 Continued research has further uncovered important oxygenated sesquiterpenes (C15H22O) such as agarospirol, jinkohol, jinkohol-eremol and kusunol, which may compose the unique olfactory profile of agarwood oil. Analysis using GC-MS showed the presence of agarofurans and agarospirol as the main compounds contributing to the signature woody notes in the smoke released from burning the agarwood. The analysis also detected hydrocarbons formed from dehydration of sesquiterpenes and decomposition of wood and resin, which make up the olfactory profile of agarwood smoke or frequently termed as incense, along with the sesquiterpenes.

Extraction of Agarwood

Similar to other natural essential oils, agarwood oil is derived from a particular extraction process. Previous scientific investigations have shown that the extraction condition is one of the major factors influencing the quality of agarwood oil. Research has been conducted to improve the quality of extractions, which resulted in the development of new methods for extraction. The most conventional method is hydro and steam distillation, which has been in practice since the earliest discovery of essential oils until present (see F-9). The newly developed unconventional methods of extraction are microwave-assisted (MAE) and supercritical fluid (SFE) extraction. Depending on the purpose of extraction, any of these methods can be used as each of them has their own advantages and disadvantages in regard to the quality and quantity of the yield, duration, cost and ability to extract the target fractions of out of the total composition.8

Generally, extraction of agarwood oil yielded relatively small amount of product when compared to that of essential oils from other sources. Despite introduction of new methods in recent years, hydro distillation remains the most relevant choice in industry due to its relatively easy operation, low operating and maintenance costs. The process requires the use of a distillation unit, which is made of a fire source, distillery pot, condenser unit and collector. The process involves several steps which start with soaking the finely grounded extractable wood in water, also referred to as fermentation process. Subsequently, the pot will be filled in with the fermented agarwood and boiled to vaporize the aromatic volatile oil content. A condenser would condense the vaporized oil into liquid form before collection by a separating funnel that separates the oil from water gravitationally.9

Hydro distillation is beleaguered with issues such as time-consuming extraction, loss of volatile compounds and degradation of valuable compounds due to thermal and hydrolytic effect, which could affect the quantity and quality of the yield. The thermal conduction and convection that take place in hydro distillation does not transfer the heat evenly to the whole sample, thus making the extraction incomplete despite the long hours. The long contact with the direct source of heat could also burn down the sample at the bottom part of the pot, which will only cause further loss of essential chemical components. While Microwave Assistance Extraction and Super critical Fluid Extraction could eliminate some of these issues, the high operating and maintenance costs, plus the complex installation and operation, make them unfeasible for large-scale production. Various modifications have been made to this conventional method in order to improve efficiency and feasibility of distillery process, such as the use of stainless steel pot to replace the copper pot, etc.

Quality Control Analysis

Generally, agarwood is sorted out based on its origin before being further subjected to a traditional grading process based on smell, color, density, size and shape. Depending on the market preference, agarwood from a particular origin can be more expensive than the others. Grading procedures used for the wood can be a little bit different from the oil. While color and density of the wood are usually linked to its resin content for the oil, these two criteria would normally depict its age and texture, respectively. As a rule of thumb, the wood densely packed with resin is usually qualified to be processed into wood chip as an incense and low quality used for oil extraction. These traditional procedures, which require an appraiser with years of knowledge and experience about agarwood still constitute the largest part of current agarwood grading analysis in industry. These appraisers are usually referred to as nose or sniffer. As the methods rely heavily on human capability, analysis is often prone to human error, further marred with challenges in documentation and standardization.

Advances in analytical chemistry in recent years have allowed for highly accurate and precise analysis of volatile molecules using techniques such as gas chromatography (GC) equipped with detectors such as mass spectrometry (MS), flame ionization detector (FID) and olfactometry (O). The instrument is able to detect and identify volatile molecules such as those present in agarwood, using separation technology. The technology uses the differential fractionation of the molecules in stationary phase to separate them at different points of time and space, generating a profile at the end of analysis. Comparison of these profiles between different samples allows for determination of the quality of a particular sample, which brings the possibility to standardize agarwood quality assessment closer. Despite advantages offered by GC techniques, which surpass the traditional grading methods, the instrument is too expensive and complex for convenient use in industry and thus, less accessible than the latter.

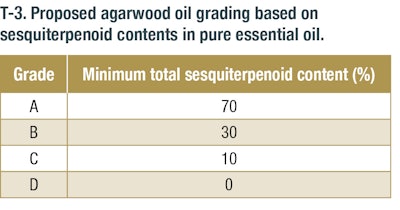

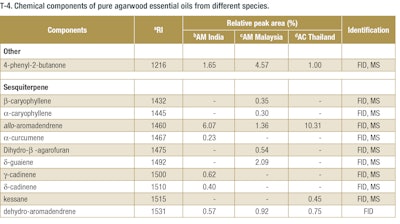

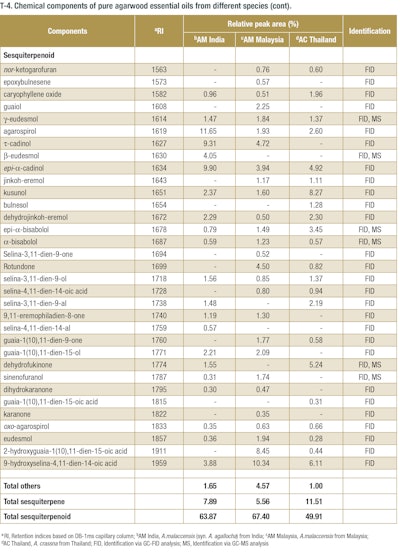

Regulatory compliance is a challenge for agarwood and its derivatives. So far there is no internationally recognized standard for agarwood and agarwood oil. Due to the absence of standardized grading system, the current pricing of agarwood still relies heavily on consumer perception and preference. This leads to adulterated and fraudulent agarwood trading, which have tainted the industry for years. The challenges in establishing the standards are often attributed to the different profiles generated for agarwood oils of different origins. Ajmal has been working closely with academic and industry partners, as well as with regulatory bodies to identify the key sesquiterpenoids as the marker compounds in agarwood oil that directly contribute to the smell of agarwood (see T-3). Ajmal further proposes that agarwood oil of particular origin should be classified separately according to their chemical compositions (see T-4).

Dahn Al Oudh (D/O) Hindi and Indian Boya refers to agarwood oil and solidified fatty material, respectively, derived from A. malaccensis that grow in North East India. D/O Hindi is extracted from low quality resin-impregnated wood or left-over wood from agarwood processing, often called as extractable wood (see F-10). The characteristic component of the oil is agarospirol in the range of 5% to 20 % (see F-11). On the other hand, Indian Boya is extracted from left over non-odoriferous which is white to pale in color. The Boya is primarily composed of C4 to C28 fatty acids and traces of sesquiterpenoids. Agarwood oil from A. malaccensis grown in Bangladesh shares almost similar characteristics with D/O Hindi with agarospirol content ranging from 5% to 10%.

Agarospirol has also been identified as characteristic component in agarwood oil is derived from A. crassna, which grow in Laos and Vietnam. The species grow in Laos produce oil with agarospirol content ranging from 5% to 20% while that of Vietnam is generally composed of 2% to 10% agarospirol, with more animalic odor profile. A. crassna is also widely cultivated in two main areas in Thailand namely Prachin and Trat. Agarwood oil from Thailand is commonly measured by the content of allo-aromadendrene in the range of 5% to 15%. On the other hand, agarwood oil extracted from A. malaccensis originating from Malaysia is predominantly composed of α-eudesmol content that ranges between 5% to 15%. Tarakan and Meruke from Meruke province of Indonesia are obtained from A. beccariana that grow in the country. The oil is characterized by the presence of jinkoh-eremol in the range of 10% to 30%.

To summarize, these findings show that agarwood oil of different origins and species may have different marker compounds that predominantly characterize the oil. This information can be further used to grade the oil according to composition of these marker compounds. However, the proposed grading method is applicable only to pure agarwood oil, as derivatives are usually adulterated with contaminants. On the other hand, further tests are required to establish safety data on agarwood oils worldwide.

Agarwood Derived Products

Practically, all parts of agarwood tree namely the wood, leaves, flowers, roots and seeds are usable depending on the target market. However, the mainstream applications of agarwood refer to the use of highly prized resin-impregnated wood (see F-12). Large pieces of resin-impregnated wood with aesthetic features are valuable for sculpture making. The wood of smaller sizes with high resin content are sold as high quality wood chips, highly valued by Middle Easterners. The wood of inferior quality is classified as extractable wood, used for oil extraction, which are valued differently in different markets. On the other hand, extract from the white wood is valuable as an ingredient in traditional medicine, particularly sought after in the Asia Pacific market. Similarly, the leaves, flowers and roots are used as ingredients in traditional medicine, the history of which stretches back to the years before centuries.

The woodchips are burned as incense to release the fragrant smoke used to scent the clothes, and spaces for personal and commercial uses (see F-13). The oil has wider applications than the wood, which include its use as pure essential oil, compounded oil or as an ingredient in fragrance products. Pure essential oil is used as fragrance solely or layered with essential oils from other sources – a practice which is common in the Middle East. Compounded oil refers to agarwood oil blended with other essential oils, widely used as fragrance or aroma therapy in the Middle East, Europe, North America and Asia Pacific. As a medicinal ingredient, agarwood is processed into various products such as dried herbs, tonic concoctions, powders, ointments and tablets for external and internal uses. Recently, the use of agarwood oil and leaves in cosmetics and skin care products has emerged particularly in the Asia Pacific. The market is expected to grow following the increasing global demand for organic-based beauty products. Ajmal is actively working on antioxidant properties of extracts derived leaves of agarwood for various applications in association with reputed research institutions.

Conclusion

In a nutshell, there is definitely an increasing demand for agarwood globally and the emergence of new agarwood-based products in the market signifies the horizontal growth and potential expansion of the agarwood market. Establishment of international standards based on scientific approach is important to regulate the quality and safety assessment of agarwood in the market. Introduction of standards and guidelines to the market is expected to produce positive impact on productivity and transparency at every point of supply chain in agarwood industry.

Acknowledgments

The authors acknowledge the generous support and encouragement from Mohd. Amiruddin Ajmal, CEO & Mr. Abdulla Ajmal, Dy. COO, R&D Team Members and Colleagues of Ajmal Perfumes. We also acknowledge technical contributions and reviews from Norul Amalina Sabri and Che Mohd Aizal Che Mohd and Azman Md Diah for the photographs and other supporting member from University Malaysia Pahang.