Rosewood (“Bois-de-rose” in French, “pau rose” in Portuguese) oil has been an item of commerce for more than 130 years. The oil is traditionally produced from the wood of felled trees of Aniba rosaeodoraDacke (syn. A. rosaeodoravar. amazonica, A. duckeiKostermans), a member of the Lauraceae family.

Rosewood is a tall, tropical, evergreen tree that can grow to a height of 30 m with a diameter at breast height (dbh) of 2 m. It possesses a straight cylindrical trunk, which is covered with a yellow-brown bark (Maia et al. 2007). It can be found growing in its natural environment in the non-flooded areas across the Amazon basin in the Brazilian states of Acre, Amapá, Amazonas, Para and Rosima. It can also be found in the Amazon region of Colombia, Guyana, Peru and Venezuela. The highest population is found in the state of Amazonas (May and Barata, 2004) where less than two trees/ha. are found (Pereira Santos et al., 2008a).

A study was undertaken by Pereira Santos et al. (2008b) to determine how to conserve the natural populations of rosewood and examine its genetic diversity among those studied, particularly in distant populations. Based on their detailed observations, the author has recommended the following:

- Trees to be sampled for breeding and conservation

- Maintenance of a genetic diversity in the gene pool nursery

- A thorough analysis of the harvested and non-harvested trees from all regions to be undertaken

- A more complete understanding of the optimum reproductive parameters and seed dispersal to be performed

Pereira Santos et al. noted, once their recommendations are followed, the future of the species would be ensured.

In Brazil, rosewood trees grow naturally in the vicinity of Burity Velho, Maués and near the Jamundá and Oyapoc rivers in the Amazonas state (May and Barata, 2004). The Brazilian National Institute for the Environmental and Natural Resources (IBAMA) issued a set of directions to the rosewood oil distillers in 1998. They were as follows:

- Rosewood harvest not permissible in certain areas

- No trees with diameter at breast height (dbh) less than 20 cm can be felled

- There is an annual amount of wood permitted to be distilled

- Re-forestation must be proportionate to the tree harvest

- A limit of 2,000 trees can be harvested annually

- The possession of an IBAMA certificate is mandatory for oil export

According to Vial-Debas (2000), despite the regulations the species is still being exploited and it is vanishing from much of its original habitat.

The first distillation of A. rosaeodorawas performed by a Frenchman (Samain) in 1875 using wood imported from French Guiana. At that time the oil was known first of all as “huile de linaloès” or “huile d’aloes,” although later it became known as “essence de bois de rose” (Record and Hess, 1943).

At that time, one of the most valuable woods known as “likari kanali” (by the indigenous people) or bois-de-rose mâle (by the French colonists) was in demand for the manufacture of furniture in France. Because of its fragrance it was particularly desirable for the construction of drawers and chests that were used for the storage of clothes and linens (Bassières, 1913).

According to Bassières bois-de-rose oil production began in 1889 in French Guiana (now known as Cayenne) with an initial production level of ca. 350 kg. By 1910 production had increased to ca. 22 metric tonnes.

During the late 17 century and early 18 century, several distilleries were constructed close to the rivers downstream from the main rosewood forest regions of Brazil so that the wood could be readily transported from the forest to the distillery. By 1929, more than 95 mt. of oil were produced.

To try and ensure that there would always be rosewood trees for felling and oil production, rosewood distillers undertook a replanting program in (the 1940’s) of natural seedlings in the forest (Barata, 2002). Typically, a strip of land within the forest was cleared where seedlings were planted, which is a process known as tunnel planting. Unfortunately, the tree growth was slow because of the overshadowing by the surrounding trees. To address this, in the 1990s, open field or plantation cultivation of natural seedling commenced in the state of Para.

Santana et al. (1997) reported that S. American rosewood oil production peaked at ca. 500 mt. in the early 1960s. They noted at that time there were 50 distilleries producing oil. According to Bechimol (2001), 15 mt. of wood are required to produce one mt. of oil. In the 1960s, some 30,000 workers were employed in the rosewood oil industry, whereas by 1990, only 2,000 workers remained employed.

Between 1997–1999, the average rosewood oil production was 38.5 mt. (Bechimol, 2002), while in 2008 it was estimated to be ca. 40 mt. More recently, Bizzo et al. (2009) reported that between January 2005 and October 2008, Brazil exported 121 mt. of oil. The actual annual level would appear to this reviewer to be 30–40 mt. of both leaf and wood oils of A. rosaeodora.

Cambell de Araujo et al. (1971) examined the oil content, linalool and linalool oxide amounts of oils produced separately from leaves and twigs of a single tree monthly for a year. They found the leaf oil varied as follows:

oil content (1.4–2.6%)

linalool (27.3–85.3%)

linalool oxides (5.3–19.7%)

The lowest oil yield and linalool content and the highest linalool oxides content occurred in February.

The twigs oil was also found to vary as follows:

oil content (1.0–2.0%)

linalool (35.7–94.3%)

linalool oxides (3.0–18.7%)

The variation in oil content and major components was similar to that found in the leaves.

A commercial sample of rosewood oil purchased in Serbia was examined using GC-FID and GC/MS by Simic et al. (2004). The oil was found to possess the following composition:

α-thujene (0.3%)

sabinene (0.5%)

β-pinene (0.1%)

p-cymene (0.1%)

limonene (0.9%)

1, 8-cineole (0.6%)

trans-linalool oxide (2.1%)

cis-linalool oxide (2.1%)

linalool (81.3%)

ocimenol (0.1%)

linalool oxide (0.2%)

terpinen-4-ol (0.2%)

α-terpineol (4.8%)

nerol (0.4%)

geraniol (1.3%)

α-copaene (0.8%)

β-elemene (0.2%)

γ-selinene (0.2%)

β-selinene (0.8%)

α-selinene (0.7%)

δ-cadinene (0.1%)

nerolidol (0.2%)

benzyl benzoate (0.2%)

correct isomer not identified

incorrect identification

f = furanoid form

p = pyranoid form

The main components of rosewood oil obtained commercially in Brazil by Maia et al. (2004) were as follows:

trans-linalool oxide (2.8%)

cis-linalool oxide (3.0%)

linalool (86.1%)

α-terpineol (2.3%)

f = furanoid form

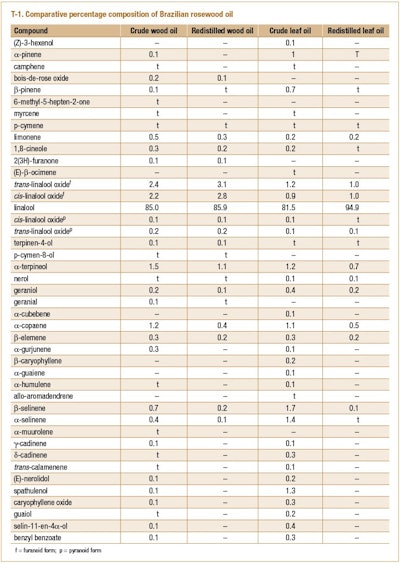

Zellner et al. (2006) compared the leaf and wood oils of A. rosaeodora of Brazilian origin. Using a combination of GC-FID and GC/MS the author examined both crude (freshly distilled) oils and redistilled oils of both leaves and wood. Their results can be seen summarized in T-1. Zellner et al. also used chiral GC to examine the enantiomeric distribution of all oils; the results of which are shown in T-2.

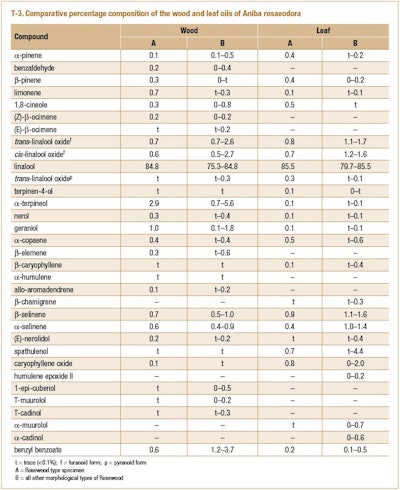

Maia et al. (2007) separately isolated oil from the leaves and wood of different morphological types of A. rosaeodora most of which were found growing on the left side of the Jatapu river in the municipality of Novo Airão (Amazonas state). One sample was obtained from the original type specimen planted by Ducke at the Zoobotanical Park of the Emilio Goeldi Museum (Belem, Para State). The oils were all produced in the laboratory by hydrodistillation from dried plant materials for 4 hr. The oil yield of the leaves of the type specimen ranged from 1.6–2.2% over a year. In comparison, the oil yield of the leaves and wood or the various morphological types was 2.4–3.1% and 1.8–3.4%, respectively.

The authors also used LC-MS analysis of the ethanolic extracts of the wood of the type specimen and the other morphological types. Although these analyses showed that the type specimen could be distinguished from the other morphological types by the composition of the non-volatiles, the volatiles as determined by GC-FID and GC/MS showed very similar oil compositions as shown in T-3 .

Lupe et al. (2008) reported on the promotion of rosewood leaf oil as a replacement for the dwindling rosewood oil. A comparison between the major components of the two oils is shown on T-4.

Eighty-two samples of trunk-wood, bark, branch-wood, roots and leaves of A. rosaeodora were collected from 10 localities in northwestern Cayenne (French Guiana) by Chartraine et al. (2009). The trunkwood samples were mostly collected from trees using an auger to remove a 10 cm long sample, which was found not to damage the trees. They found the trunk and branch wood samples, which possessed the best lavender-like aroma, ranged in oil contents 0.64–3.2% with the highest yields from the trees with the largest dbh. The root oil yields ranged from 0–1.22%, the bark oil yields from 0.41–1.34% and the leaf oil yields 0.18–0.55%. It was also found the average trunkwood oil from fruiting trees was 1.78% compared to 1.13% for non-fruiting trees. The author’s concluded, mixing the oils from small branches and leaves was in their belief detrimental to the aroma of the oil. They also found oils produced from trees from the northern zone of French Guiana (Paracou) were lower than oils produced from other areas. Also they found these oils possessed some (+)-linalool along with the expected (−)-linalool.

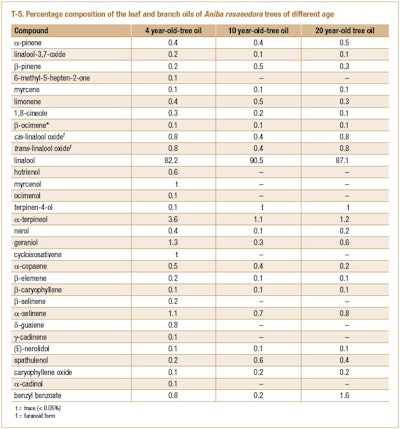

Using two dimensional gas chromatography coupled with quadruple mass spectrometry (GC-GC/qMS), Fidelis et al. (2013) analyzed oils produced by steam distillation from the leaves and branches of 4-, 10- and 20-year-old trees. The results of this study are reported in T-5. The study by Fidelis et al. (2012) presented the same results as can be seen in T-5 using the same GC-GC/qMS analysis.