Preamble

The terms ‘product’ and ‘ingredient’ will be used interchangeably throughout this article. A product is a fragrance raw material which is also a fragrance ingredient. For the purposes of the IFRA Green Chemistry Compass, the term 'product' refers to a fragrance ingredient.

Introduction – Policy Context and Drivers

With the growing concerns over consuming the earth's finite resources and the need to address global challenges such as climate change, all actors ranging from political and governmental institutions to commercial and civil society organizations are keen to promote actions towards a greener future. To make these actions tangible for the fragrance and flavor (F&F) industries, IFRA and its sister organization IOFI have developed a common sustainability charter for the F&F sectors which sets the framework for collective industry action towards greater sustainability.1

The IFRA-IOFI Sustainability Charter makes a specific commitment: “We foster the application of green chemistry principles.” In order to make this commitment actionable, the IFRA Green Chemistry Compass Tool was designed to guide the fragrance industry in evaluating and enhancing the environmental and health profiles of their products. The IFRA Green Chemistry Compass is grounded in the principles of green chemistry, which aim to reduce or eliminate the use and generation of hazardous substances in the design and manufacture of fragrance ingredients. It offers a comprehensive framework that can be used by companies of all sizes to assess their current practices and identify opportunities for improvement, that also align with the United Nations Global Sustainable Development Goals (SDGs).

The global SDGs were launched in 2015 and the 17 goals frame the actions needed to transform the world for a more sustainable future.2 The European Green Deal passed by the European Commission in January 2020 translated the global SDG framework into a package of policy proposals for Europe.3 Europe should achieve a green and digital transition by 2050 and the Green Deal covers many aspects from farming to energy and innovation. Whilst there are some accepted standards for certain aspects of corporate "green" performance, like the Carbon Disclosure Project (CDP), the Science Based Targets Initiative (SBTi), and the USDA Biopreferred® Program, there is a lack of specific sectorial industrial standards that can apply to a particular sector such as the fragrance industry.4,5,6

Introduction – The IFRA Green Chemistry Compass Tool

For the fragrance industry, which may be considered a part of the larger chemical industry, a common starting point is to refer to one or more of the 12 principles of green chemistry, a framework developed by Anastas and Warner.7 To develop a more harmonized and broadly accessible approach to foster the application of green chemistry principles, IFRA partnered with Beyond Benign to develop the IFRA Green Chemistry Compass.8 It made an open call for interested scientists from fragrance industry member companies to form a working group, together with the independent scientists from Beyond Benign. The approach was designed to be fully inclusive, ensuring that both small and large companies are equipped with sustainability tools that enable them to evaluate the ingredients they manufacture.

The overall objective of the IFRA Green Chemistry Compass is that companies can learn and improve with regard to the manufacture of greener products, and not to grade one manufacturer as better than another. All 12 principles of green chemistry were considered for inclusion. The most relevant principles were expanded upon and, when necessary, updated to include new elements relevant to the fragrance industry today, given scientific and industrial advances.

It is important to note that green chemistry is only one element in evaluating the overall sustainability of a fragrance ingredient and other aspects need to be considered to take a more holistic view, such as land and water use, or ethical standards. The IFRA Green Chemistry Compass considers the manufacture of fragrance ingredients and certain safety aspects of the final fragrance ingredient. For practical reasons, hazard classifications are used as one criterion when considering reagents and products. A risk assessment approach would be more appropriate, but at this time an approach that would be easy to apply in this framework was not identified. The green chemistry tool can aid companies in adopting a "safe and sustainable by design" mindset by applying these principles to their fragrance ingredient developments and manufacturing in a systematic manner.

Adapting the 12 Principles of Green Chemistry to the Fragrance Industry

The Fragrance Industry uses more than 3500 commercial ingredients as outlined in the IFRA Transparency List.9 These ingredients range from synthetic materials made from fossil and renewable carbon sources using traditional chemistry, to natural extracts and materials made using biotechnology.10 The approach of the IFRA Green Chemistry Compass can be applied to the full spectrum of ingredients.

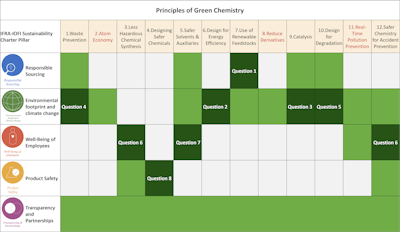

The project team started from the 12 Principles of Green Chemistry which can all be applied to the flavor and fragrance industries. For the purposes of developing the IFRA Green Chemistry Compass, the most relevant principles were prioritized and mapped against the five focus areas of the IFRA-IOFI Sustainability Charter and the UN Global Sustainable Development Goals (SDGs). This creates a holistic interconnected matrix helping to visualize the bigger picture of priorities and impact.

Three green chemistry principles "Atom Economy," "Real-Time analysis for pollution prevention" and "Reduce Derivatives" were considered less relevant or in part covered by other principles, as detailed below.

For each of the remaining 9 principles the working group devised a set of questions that need to be answered by the ingredient manufacturing company so that in the end, an approach to classification in 1 of 3 categories is achieved: "Most preferred," "Needs improvement," "Least preferred." Whilst this approach may be considered subjective, these categories were made with consideration for current industrial practices. No doubt over time these categories will be reviewed and updated. The logic used for each of the retained green chemistry principles will be briefly reviewed following the order of the principles and the links between the IFRA-IOFI Sustainability Charter commitments. These links are illustrated in F-1 below.

F-1. Connection between the five IFRA-IOFI Sustainability charter commitments, the 12 Principles of Green Chemistry and resulting Green Chemistry Compass Questions.courtesy of IFRA

F-1. Connection between the five IFRA-IOFI Sustainability charter commitments, the 12 Principles of Green Chemistry and resulting Green Chemistry Compass Questions.courtesy of IFRA

Green Chemistry - Principles and Questions

Principle 1: Waste Prevention

Question 4: How much waste is generated in the process?

Waste reduction in chemical processes can reduce the overall environmental footprint of a product lifecycle, therefore reducing the overall impact on ecosystems and climate change. Waste generation is a measure of the efficiency of the manufacturing process.

Several metrics were considered including Process Mass Intensity (PMI = (sum of mass of materials)/ (mass of isolated product)), used extensively in the pharmaceutical industry, atom economy (AE = (MW of product)/ (Sum of MW's of all reactants)) and E-factor (E-Factor = (Total mass of waste from process)/ (total mass of product)). In conclusion, it was decided to use the E-factor as it is the most focused measure of waste generation, whereas PMI is more linked to process efficiency and AE does not directly assess waste generation. The thresholds were set in line with common industry guidance, with <5 being the most preferred.11

Principle 2: Atom Economy

This principle was not considered explicitly as it is partly captured by Question 4 as a measure of waste; an ingredient manufactured with very high atom efficiency would likely have a low E-factor and vice-versa.

Principle 3: Less Hazardous Chemical Synthesis

Question 7: Process Safety and Hazards: Do the reagents or raw materials pose any physical, health or environmental hazards?

For this principle, a calculation is performed based on all the reagents used for the ingredient manufacture and their hazard classification (H-statements). For each reagent, the physical, health and environmental hazard classifications used are the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) of the ingredients listed on the Safety Data Sheets (SDSs) of the reagents.12 Physical hazards encompass hazards such as flammability, combustibility, oxidizers, and explosivity. Health hazards include a range of acute and chronic mammalian toxicity from mild to extreme hazards. Environmental hazards include hazards to the environment and ecosystems, including aquatic toxicity and ozone depletion. The aggregated score of the reagents, based on the severity of H-statement and frequency of occurrence is used to define the 3 groups. The calculation runs automatically within the IFRA Green Chemistry Compass software tool. If there are no data for a reagent in the relevant section of the SDS the score is defaulted to “least preferred.”

Principle 4: Designing Safer Chemicals

Question 8: Does the product pose any physical, health or environmental hazards?

In a similar fashion to Principle 3 above, the GHS classifications of the fragrance ingredient (the product) are used to calculate a score for the final product and based on this score it can be placed in one of the 3 categories.

The regularly updated IFRA-IOFI Labelling Manual can be used to find GHS hazard statements for fragrance ingredients. Equally, the SDS of the ingredient can be used.13 If there is no data in the relevant section of the SDS the score is defaulted to “least preferred.”

Principle 5: Safer Solvents & Auxiliaries

Question 6: What type of solvents are used?

Solvents are used for both the conventional organic synthesis of fragrance ingredients and for obtaining natural extracts, in particular absolutes. There is an existing categorization of solvents in terms of their desirability developed by the pharmaceutical industry, the American Chemistry Society (ACS) Green Chemistry Institute's Pharmaceutical Roundtable Solvent Selection Guide, and this was adapted to the typical solvents used by the fragrance industry to establish the 3 groups.14 If the solvents are not recycled the score is downgraded, however, if made from renewable carbon the score can be improved.

Principle 6: Design for Energy Efficiency

Question 2: a) To what extent is the process for making this product energy-intensive?

b) Is renewable energy used in whole or in part in the process?

Reducing energy use and favoring more renewable forms of energy reduces net emissions and yields lower carbon footprints.

For this principle, the working group considered several options to gauge the energy intensity of a given manufacturing process.

If known, internationally recognized standards in line with the Greenhouse Gas protocols (GHG), such as ISO 14040/14041 should be used to measure carbon footprint (cradle to gate) as a means of establishing a value for this question.15 To date, relatively little data are publicly available for fragrance ingredients, although this situation is evolving. Multi-step, high-energy, low-yield manufacturing processes will inevitably lead to high footprints. The thresholds selected will need to be updated over time as more data become available and <10kg CO2/kg is consistent for example with Genomatica's manufacture of 1,3-butylene glycol (low temperature and pressure) biotechnology.16 Land use change (LUC) and Biogenic carbon contributions – if relevant - should be excluded from the carbon footprint value used, as these elements are not linked to energy efficiency.

Alternatively, the temperature, pressure and time conditions for the most energy-intensive step in the manufacturing process can be used. The thresholds were set in line with typical conditions used in the fragrance ingredient manufacturing industry (most preferred <5 atm, -10°C-50°C, <24 hours). If the energy source to generate the temperature and pressure is >50% renewable, the score can be improved.

Principle 7: Use of Renewable Feedstocks

Question 1: Is the product derived or extracted in whole or in part from a renewable, Biomass Balance (BMB) or carbon capture resource?

Where fossil carbon is used today, the overarching goal is to encourage a move for ingredient manufacturing from virgin fossil carbon to renewable or recycled carbon. Whilst today fossil carbon plays a major role in the fragrance industry, there are a number of fragrance ingredients that can be manufactured either from fossil or renewable carbon.17 In addition, there have been two relatively recent developments that can further accelerate the transition away from virgin fossils: bio-mass balance and carbon capture. Bio-mass balance (BMB) mixes renewable and fossil starting materials, like methane or ethylene, and certifies the mass of the final ingredient that can be attributed to the renewable source.18 A number of BMB fragrance ingredients are already available. Carbon capture has so far not been commercially applied to fragrance ingredient manufacture, but the process to capture CO and CO2 and transform them into ethanol has been industrialized and we can imagine that it will be applied to fragrance ingredient synthesis in the future.19

The threshold of >50% renewable/BMB/ carbon capture was used to distinguish the groups of "needs improvement" from "least preferred" as this is the limit in ISO 16128 to define a material of "natural origin."

Principle 8: Reduce Derivatives

This principle was not considered actionable for the fragrance industry in the context of the IFRA Green Chemistry Compass. The expert group could not easily define specific parameters to assess fragrance ingredients against "reduce derivatives." In addition, this principle is very specific to synthetic chemistry and therefore would increase the complexity of the compass tool significantly since this tool is designed to also cover natural ingredients.

Principle 9: Catalysis

Question 3: a) What type of catalyst, if any, is used in this process?

b) What is the mol-recycle number for the catalyst used (if applicable)?

The use of catalysts is, in principle, good in that it typically allows lower manufacturing temperatures and higher yields, and in the case of the fragrance industry allows stereo-selectivity where 1 isomer has a specific olfactive profile different from that of the racemic mixture.

Many factors can determine how sustainable a catalyst is within a chemical process, including toxicity, earth abundance in the case of metal catalysts, efficiency, reusability/recyclability, selectivity and more.

The overall logic of preference is Biobased > non-metal > earth-abundant metal > precious metal. With this consideration, the thresholds favor biobased catalysts like enzymes as group 1 most preferred, then non-metal over metal catalysts, and within the metal catalysts there is a further division based on toxicity and earth abundance; certain metals are scarce, so extraction is difficult and unsustainable. If the metal catalyst has a high turnover number, > 1000, the score is improved.

Principle 10: Design for Degradation

Question 5: To what extent is the product biodegradable?

Biodegradation is the process by which organic molecules (comprised of carbon) are completely broken down by microorganisms into harmless products (e.g., carbon dioxide, water, and mineral salts). Biodegradability is a material property that describes the potential for complete biodegradation under environmental conditions (e.g., rivers, wastewater treatment plants, lakes, ponds, etc.). In order to classify a material as biodegradable it needs to reach certain pass criteria in standardized test methods (e.g., OECD TG 301).20 The ultimate goal is that all fragrance ingredients will be readily or inherently, ultimately biodegradable, leaving no trace in the environment after use.

Within the fragrance industry, a group of experts has written a white paper that details the conditions for an ingredient to be considered “readily biodegradable,” corresponding to the category “most preferred” and “inherently, ultimately biodegradable” corresponding to the “needs improvement” category, based on the results from the screening test methods OECD 301/310 (and equivalent) and OECD 302 (and equivalent).21 Ingredients that either do not pass these conditions or for which there are no data are considered to be in the “least preferred” category.

For Natural Complex Substances (NCS) like essential oils, biodegradability can be assessed either on the NCS itself or by considering the biodegradability of their constituent parts as detailed in the white paper.21 Natural Complex Substances (NCS) are defined by the EFEO-IFRA Guidelines on substance identification and sameness of Natural Complex Substances (NCS) under REACH and CLP as "a very diverse family of substances that are notably used as ingredients in fragrance formulations and [directly or indirectly] added to cosmetic and other consumer products. NCS is well described in ISO standard 9235 (Aromatic natural raw materials - Vocabulary). The most common NCSs are Essential oils; Concretes and Absolutes; Oleoresins and Resinoids; CO2 extracts; Infusions and alcoholic extracts."

For defined chemicals where no data are available, biodegradability can be predicted using software such as the BIOWINTM estimation program, part of the EPI SuiteTM, provided by the United States Environmental Protection Agency.22 However, such predictions are not considered sufficient and should therefore not be used to assess which category an ingredient should be placed in, with a narrow exception related to constituents of NCS as detailed in the white paper.

Principle 11: Real-Time Pollution Prevention

This principle was not considered actionable for the fragrance industry, and it was decided by the expert group that no specific parameters to assess fragrance ingredients against "real-time pollution prevention" could be easily defined.

Principle 12: Safer Chemistry for Accident Prevention

Covered by Question 7 (Principle 3).

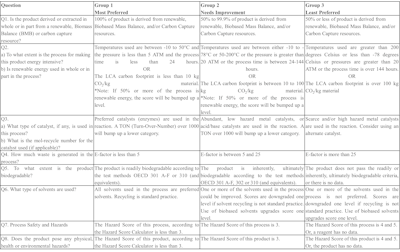

A summary of the criteria thresholds is provided in T-1 below:

T-1. Summary of Threshold criteria to calculate the green chemistry score of fragrance ingredients into 3 groups "Most preferred," "Needs improvement" and "Least preferred."courtesy of IFRA

T-1. Summary of Threshold criteria to calculate the green chemistry score of fragrance ingredients into 3 groups "Most preferred," "Needs improvement" and "Least preferred."courtesy of IFRA

Summary and Conclusion

The IFRA Green Chemistry Compass offers a new, comprehensive, and harmonized framework tool that helps companies of all sizes assess their current practices and identify opportunities for continuous improvement.

The IFRA Green Chemistry Compass is the first attempt at a cross-industry agreement on green chemistry principles for the fragrance industry by building on the collective experience of the industry and independent experts. In this way, fragrance manufacturers, large and small, and all around the world can benefit from a harmonized assessment tool that was developed by global green chemistry experts. This tool is tailormade to fragrance ingredients and recognizes the particularities of the fragrance sector.

The IFRA Green Chemistry Compass has been successfully piloted and was subject to a global public consultation. The comments received during the global public consultation are incorporated into the harmonized tool. The IFRA Green Chemistry Compass complements the individual green chemistry approaches published by fragrance companies and customers.23,24,25,26

The link between the IFRA Green Chemistry Compass, the five pillars of the IFRA-IOFI Sustainability Charter and the UN global Sustainable Development Goals (SDGs) is illustrated in F-2 below.

F-2: Connection between the five pillars of the IFRA-IOFI Sustainability Charter, the 12 Principles of Green Chemistry, the Green Chemistry Compass Questions and the UN SDGs.courtesy of IFRA

F-2: Connection between the five pillars of the IFRA-IOFI Sustainability Charter, the 12 Principles of Green Chemistry, the Green Chemistry Compass Questions and the UN SDGs.courtesy of IFRA

Call for Action

Whilst the use of the IFRA Green Chemistry Compass tool is voluntary, we encourage its use and uptake since it is an open-source resource for the fragrance industry and any interested stakeholders all over the world. With this innovative and harmonized tool, big and small companies can assess the profile of the fragrance ingredients they currently make or intend to make, and identify ways to improve for a better future.

The IFRA Green Chemistry Compass tool can be downloaded free of charge from the IFRA Website [9]. A tutorial video and detailed guidance notes are also available on the IFRA website. For additional questions about the use of the IFRA Green Chemistry Compass, please contact [email protected].

Key Takeaways

✓The IFRA Green Chemistry Compass is a harmonized tool to implement the IFRA-IOFI Sustainability Charter commitment 2.3 "We are inspired by Green Chemistry."

✓It incorporates the relevant green chemistry principles across all aspects of fragrance ingredient production, ranging from starting reagents, manufacturing, and considering the health and safety aspects of the reagents and products to identify the areas for improvement.

✓It drives forward looking conscious and systematic reagent and ingredient choices that are less harmful to people and the planet.

✓It benchmarks progress towards incorporating green chemistry principles.

✓It instills a sustainability mindset by applying sustainability principles in a systematic manner thereby helping companies to improve their sustainability business case.

✓The IFRA Green Chemistry Compass is available as an open-source tool from www.ifrafragrance.org.

Disclaimer

The IFRA Green Chemistry Compass is designed to be used for forward-looking internal purposes only. The IFRA Green Chemistry Compass is not suitable to serve as a basis for making B2C or B2B claims. The compass tool provides general guidance and is not meant to be a substitute for a company doing its own due diligence on its ingredients and manufacturing processes. The compass draws on the experience of leading companies in the flavor and fragrance industries that already have their own tools and provides an accessible harmonized tool for all companies to use, particularly small and medium-sized companies that do not have the resources to develop their own tools.

Acknowledgments

IFRA Green Chemistry Project Team: Marcus Eh (Symrise), Elena Galiano (IFF), Cyril Gallardo (Mane), Hans Holger Gliewe (IFRA), Richard Illi (Essencia), Paul Jones (IFF), Bhuvana Nageshwaran (Ultra International), Hiroyuki Matsuda (Takasago), Amy Perlmutter (Beyond Benign), Fabrice Robvieux (dsm-firmenich), Sandeep Srivastava (IFRA), Gaetesh Tampi (formerly IFF), Hazal Ustundag George (dsm-firmenich), Marta Varela (IFRA), John Warner (The Technology Greenhouse).

References

1. https://ifra-iofi.org

2. https://sdgs.un.org/goals

3. https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en

4. www.cdp.net and Baumast, A. (2013). Carbon Disclosure Project. In: Idowu, S.O., Capaldi, N., Zu, L., Gupta, A.D. (eds) Encyclopedia of Corporate Social Responsibility. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-28036-8_559.

5. https://sciencebasedtargets.org

6. https://www.biopreferred.gov/BioPreferred/

7. Anastas, P. T.; Warner, J. C. Green Chemistry: Theory and Practice, Oxford University Press: New York, 1998, p.30.

8. https://www.beyondbenign.org

9. https://www.ifrafragrance.org

10. Surburg,H , Panten,J. (2016), Common Fragrance and Flavor Materials (6th Edition), ISBN-10:9783527331604, Wiley-VCH.

11. Sheldon, R. A., The E factor 25 years on: the rise of green chemistry and sustainability, Green Chem., 2017,19, 18-43, DOI: https://doi.org/10.1039/C6GC02157C

12. https://unece.org/transport/dangerous-goods/ghs-rev10-2023

13. https://ifrafragrance.org/policy/labelling-manual

14. https://www.acsgcipr.org/tools-for-innovation-in-chemistry/solvent-tool/

15. https://ghgprotocol.org

16. Pacheco, R. Huston, K. (2018). SOFW Journal 11/18, Volume 144, Thannhausen, Germany, 12-15.

17. J.Warr, R.Cazalet, C. Detable (2022) Carbon Footprinting of Fragrances – Cradle To Gate. IFSCC Magazine 24(4), 265.

18. http://www.iscc-system.org

19. Handler et al (2016), Life Cycle Assessments of Ethanol Production via Gas Fermentation: Anticipated Greenhouse Gas Emissions for Cellulosic and Waste Gas Feedstocks Ind. Eng. Chem. Res. 2016, 55, 12, 3253–3261, https://doi.org/10.1021/acs.iecr.5b03215

20. OECD (1992), Test No. 301: Ready Biodegradability, OECD Guidelines for the Testing of Chemicals, Section 3, OECD Publishing, Paris, https://doi.org/10.1787/9789264070349-en.

21. https://ifrafragrance.org/docs/default-source/white-papers/ifra-white-paper-biodeg-statements_20230523_final.pdf?sfvrsn=3d90df6b_8

22. https://www.epa.gov/tsca-screening-tools/epi-suitetm-estimation-program-interface

23. Phan, T.V.T, Gallardo, C., Mane, J., GREEN MOTION: a new and easy to use green chemistry metric from laboratories to industry, Green Chem., 2015, 17, 2846-2852, DOI: https://doi.org/10.1039/C4GC02169J

24. Eckelman, M.J., et. al., Applying green chemistry to raw material selection and product formulation at The Estée Lauder Companies, Green Chem., 2022,24, 2397-2408, DOI: https://doi.org/10.1039/D1GC03081G

25. Tampy, G. The IFF Green Chemistry Assessment Tool, in Handbook of Green Chemistry: Online, Wiley, April 17, 2018, DOI: https://doi.org/10.1002/9783527628698.hgc123

26. https://www.firmenich.com/ingredients/synthetics