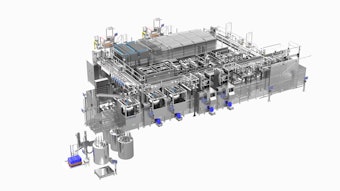

On November 23, 2025, flavor and fragrance company IFF announced the implementation of the Colibri robot in its Chin Bee production facility. This advanced industrial dosing system can produce fragrance sample batches on demand in minutes, according to the company’s press release.

The new robotic dosing system has been installed at the company’s cross-category scent and taste production facility in Chin Bee, Singapore. The new system can handle multiple ingredients simultaneously and can operate four times faster than the previous dosing system, significantly boosting automation.

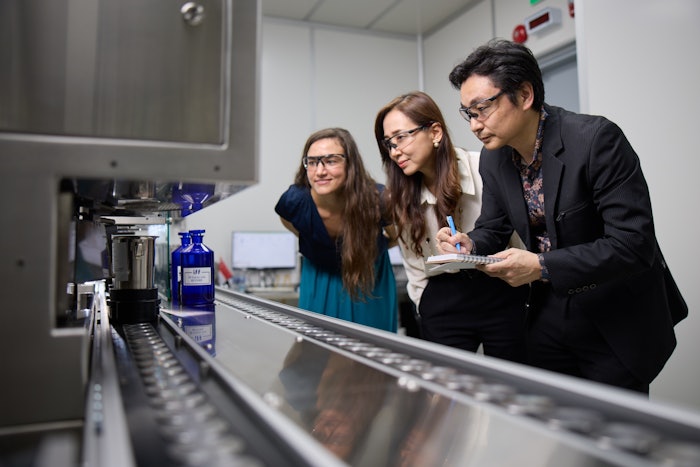

“The installation of this new automation system at IFF Chin Bee underscores IFF’s commitment to continued investment in Greater Asia, one of the fastest growing fragrance markets globally,” said Ramon Brentan, vice president and regional manager IFF Scent in Greater Asia. “It strengthens our ability to support demand in the region with enhanced speed, quality and precision.”

According to the press release, the Chin Bee site can now produce 200 sample fragrance batches in eight hours, a process that previously took 24 hours. Other IFF locations are also incorporating this new enhanced system. The company hopes that the implementation of the new dosing system will reduce time to market and empower perfumers to innovate with more agility.