Vanilla is, and will certainly remain, one of the most appreciated flavors in the world. Grown in tropical areas around the world, vanilla is mainly grown in Madagascar. Its supply is subject to variability in availability, price and quality. In recent years, vanilla beans prices have increased greatly due to climate issues and speculation, alongside with a decrease of quality. The large demand for vanilla in sweet flavors cannot be met by the limited amount of cultivated vanilla beans.

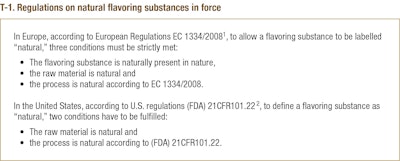

Vanillin (4-hydroxy-3-methoxybenzaldehyde) is the main organoleptic characteristic aroma component, naturally occurring in cured vanilla beans between 1-2% of the dry matter. In order to satisfy the increasing global demand for this highly favored flavor, ingredients suppliers have developed several types of vanillins identical to the one present in vanilla beans, meeting different labels, either synthetic or more recently natural to meet the increasing natural trend market demand (see T-1).

Overview of industrial synthetic and natural pathways to obtain vanillins

The current offer for vanillin is quite vast; F-1 gives a large and comprehensive landscape of vanillins available on the market.

Originally, vanillin came from vanilla beans where it is present as glucovanillin, linked to a carbohydrate moiety and released by the curing process. Vanillins can now be largely grouped into three categories:

- Synthetic vanillins: Nowadays, the very large majority of vanillin used in the flavor and food and beverage industry are synthetic vanillin. Most of the synthetic vanillins are produced from catechol by a first step of methylation leading to synthetic guaiacol, followed by formylation with glyoxylic acid. Other types of synthetic vanillin are produced by chemical oxidation of the sulfitic waste, namely the brown liquor, of the paper industry leading to vanillin from lignin.

- EU natural vanillins: Driven by consumer demand for natural flavors in the 90’s, a growing interest to produce natural vanillin through bioconversion from sources other than the vanilla bean was observed. One of the most intensively studied processes to produce natural vanillin is the bioconversion of ferulic acid, naturally occurring in the cell walls of plants such as rice or maize.3-9, 22,23 Vanillin obtained from ferulic acid, available on the market since the 2000’s10, strictly meets the EU and U.S. regulations on natural flavors.

- U.S. natural vanillins: Eugenol is naturally occurring in clove. Because eugenol is an antiseptic compound, the biotransformation of eugenol to vanillin is difficult.10-16

The vanillin ex-eugenol available on the market is produced by conversion of eugenol to isoeugenol followed by catalytic oxidation,17,18 process conditions not meeting the definition of natural process according to EU regulation and accepted as natural in the U.S. market.

Curcumin naturally occurring in curcuma is another natural precursor. Though described in the literature, the bioconversion of curcumin to vanillin is tedious19 and ex-curcumin vanillin available on the market is mainly produced by the Mallinkrodt process,20, at high temperature (> 250°C) and high pressure (> 100 mbar). These process conditions do not fulfill the definition of natural process stated in Regulation (EC) N° 1334/2008.

Guaiacol is a naturally-occurring molecule that can be derived from guaiacum or wood creosote. Nowadays, natural guaiacol is sustainably obtained from renewable wood such as beech, pine or oak. Guaiacol itself is a flavoring substance (FEMA# 2532) displaying a smoky, bacon note contributing to the flavor of many substances such as whiskey and roasted coffee.

U.S. natural vanillin was recently produced by Solvay at industrial scale from natural guaiacol by a process compliant with the FDA regulation in force. Rhovanil US Nat from natural guaiacol displays a pure vanillin profile, making it the perfect substitute to synthetic vanillin for US natural flavors, unlike other US natural vanillin, such as ex-eugenol vanillin displaying unpleasant spicy, smoky and eugenol facets. As prices can vary greatly depending on availability, processes and labeling, it is key to rely on authentication methods to guarantee transparency to customers.