Presented by Perfumer & Flavorist magazine, Flavorcon 2018: Where Delicious Innovation Begins featured 2.5 days of presentations from leading flavor and product development experts, as well as a flavor expo. More than 550 attendees and over 40 exhibitors from 24 countries attended this year’s event, which was held at Harrah’s Resort and Casino in Atlantic City, New Jersey on Nov. 13-15, 2018. The interactive conference was uniquely tailored for flavorists, consumer packaged goods professionals, applications staff, food scientists, sensory staff, sales experts and other professionals involved in the development of flavors and food and beverage products.

Insight in Innovation With Subway

Opening keynote, Rodolfo Estrada, director of culinary/R&D/innovation LATAM for Subway, discussed Subway’s approach to menu and product development.

During his talk, Estrada shared Subway’s multi-step process to create its products. Starting with ethnographic and thematic research, the company highlights cultural opportunities in the market and identifies the white spaces that the product would address. Next, the process moves into the drafting stage with conceptual development, prototyping and consumer research. Lastly, the product moves into market testing and finally to the launch stage. For example, chicken is the primary protein for Caribbean consumers. Estrada’s team then researches the local seasonings and spices to create a dish on the menu that highlights the Caribbean dining culture. However, there’s always room for a product to evolve, even after the launch and market test phase, Estrada explained.

Meeting Demand, Reformulating Flavors

The conversation moved from the finished food process to flavor development in the next keynote presentation by Matthias Guentert, Ph.D., flavor consultant, and Ketan Shah, consulting senior flavorist for Esha Flavor solutions. The two speakers discussed the relationship between trends and flavor development and how formulations are evolving to fit the needs of the conscious consumer.

“We as consumers have become a lot more demanding,” said Guentert. “We have more choices and we want more choices. We feel good about what we do, what we eat. We are socially conscious. This is credited [largely] to millennials.”

In recent years, the largest trend impacting flavors has been the demand from consumers for natural, free-from and reduced sugar/salt products – each bringing its own unique set of challenges. Guentert mentions flavors with modifying properties (FMPs) as a solution to address formulation challenges impacted by these trends. FMPs improve and maintain the overall taste without imparting a flavor. When using FMPs, however, flavorists need additional sensory data with use level and maximum use levels.

For natural flavors, flavorists must use a limited palette and provide extra documentation to verify its natural status. In creating flavors with reduced sugars, often artificial and natural sweeteners must be added to the equation to regain its flavor.

“Removing the salt, sugar and calories are becoming more and more and common,” said Shah. “It is challenging for the flavorist side ... a lot of times you end up concentrating the flavor so much that there are solubility issues.”

How Hot Do You Like It?

Once thought of as a niche segment in the food and flavor world, spicy and hot flavors have continued to see solid market growth and product diversification, including ghost pepper, habañero and Sichuan flavors. Shane McDonald, principal flavor chemist for Kalsec, discussed the global market for specialty peppers.

“According to Kalsec data, about 90% of U.S. consumers and 80% of European consumers enjoy hot and spicy foods,” said McDonald. “This is a growing trend. One out of four U.S. consumer and one out of five European consumers are eating more spicy foods than they did one year ago.” Chefs, product developers, and flavorists are utilizing different specialty peppers to add depth, heat and complexity to their creations.

In addition to overall growth and interest in spicy and hot flavors, consumers are also more concerned about the type of pepper they’re consuming. According to a Kalsec study, 36% of U.S. consumers reported that the source of the heat was important. Among the top sought-after peppers, jalapeños were rated the highest at 62%, cayenne at 59% and chipotle at 54%.

Grill Flavors For the Future

From hot to smoky flavors, the conversation turned to the future of grill flavors with a presentation from Deepthi K. Weerasinghe of dP3 Consulting. During “The Future of Grill Flavors: Overcoming Safety Concerns,” he reviewed the recent regulatory status of grill flavors and how flavorists can create safe effective flavors.

In response to questions posed by consumers, the EU banned the use of Grillin’ 5078 and Grillin’ CB-200SF in spring 2018 due to concerns over safety. In an opinion published in the EFSA Journal, the panel determined that a substantial portion of the flavoring compounds were unidentifiable and the safety of Grillin’ CB-200SF was undetermined. Following a review of the literature, Weerasinghe shared his data and insight performing a headspace GC-O, GC-MS analysis on several grill and smoked flavors. While sharing his insight, he stressed that the future of grill flavors will come down to “reducing the bad actors that are formed during grilling,” such as the unidentifiable compounds and carcinogenic components.

Do it for the Instagram

Following this presentation, the topic of trends changed from what’s hot to what’s memorable and experiential. During “Food Today: What’s Brewing & Cooking,” Amy Marks-McGee, founder of Trendincite, provided insight into emerging flavor and food trends and how the experience economy is changing consumers’ perceptions and expectations.

Marks-McGee started her presentation with a look at the emergence of food museums like the Museum of Ice Cream and The Cado (an avocado-themed museum) and how consumers, especially millennials, flock to them for Instagram-friendly photo opportunities and interactive experiences. Similarly, restaurants, bars and cafes have found other ways to create memorable experiences, including speakeasy-style bars and film-themed events. Other trends discussed during her presentation include novel flavor crossovers in products (Taco Bell chips, Sour Patch Kid yogurts, and Hellman’s ice cream) and creative packaging (cold/heat sensitive labels, VR/AR packaging and beverages in the shape of the product’s flavor).

FEMA GRAS and Regulating Flavors 101

Wrapping up the day of conference presentations, Joanna Drake, general counsel for the Flavor and Extract Manufacturers Association (FEMA) spoke about establishing a regulatory authority for flavor materials and issues surrounding flavor labeling.

During her presentation, Drake provided background information about FEMA, how the association communicates between U.S. regulatory authorities and the flavor industry, and labeling requirements for flavors. FEMA’s overall mission is to further the business interests of its members through its sound scientific program, designed to promote the safe use of flavors. Key activities of the association include sponsorship of FEMA GRAS and flavor safety programs.

“If a flavor ingredient doesn’t have regulatory authority to be used as flavor, it can’t be labeled as flavor,” said Drake. “They are separate—regulatory authority and labeling—but the labeling conclusions really depend on having an appropriate regulatory authority to use. When you are formulating ... the first step is [to ask] do I have regulatory authority to use as flavor? Then you can do the analysis on how it can be labeled.”

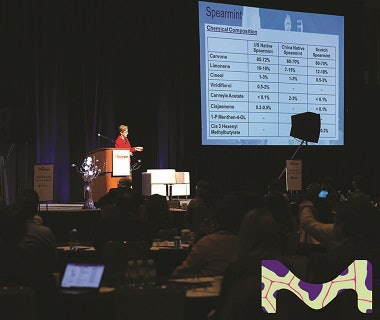

Formulating Fresh Flavors in Oral Care

Day 2 keynote speaker, Cataline Lee, worldwide director of global flavor and fragrance for Colgate Palmolive Company, presented “Decoding Flavors for Oral Care,” where she discussed global flavor trends for oral care and the various mints that Colgate uses.

“First of all, we really have to know the stability [of materials]. We have to provide sensations in order to innovate … and we also have to identify the best masking solutions,” said Lee. “Here is where our hero ingredient comes in – mint oil.”

Lee highlighted how mint oil addresses many of the formulation challenges of oral care flavors. Since mint is high in menthol, it provides the application with an ability to mask undesirable and off notes. Mint also provides oral care its sensory sensations due to its ability to impart a refreshing, cooling effect. Lee went on to describe the two most commonly used mints, particularly in the U.S.: Mentha arvensis and Mentha piperita. Beyond the U.S., Lee described how cinnamon, clove, spice and vanilla flavors are used in oral care products to provide a sense of warmth in India. Additionally, citrus oil and floral flavors are used in regions like Asia and the Middle East, respectively.

A Global Take on Cuisine

Switching from fresh to savory, the second presentation of the day featured insight from chef Richard Calladonato, former executive chef and director for Campbell’s. In “Developing Flavor: Where Culinary Classics Meet Flavors of Tomorrow,” Calladonato discussed how the preparation of ingredients is key to creating a different flavor profile for the same dish. He used grilled cheese and Pad Thai as examples.

To demonstrate how the same ingredients can create different flavors, he sampled a traditional chicken broth with savory notes and one that provided a twist on the traditional flavor that imparted a slight bitterness. “What they are really looking for is the next generation of flavor, they are looking for that little hunk of cheese. They are looking for that Pad Thai that tastes authentic in a consumer food,” Calladonato explained.

Superfoods and Novel Citrus Flavors

Following the talk on trends, the conversation moved back to materials with a presentation from Danny Hodrien, managing director and chief flavorist for F&F Project Ltd., about superfoods (specifically Maqui berries and watermelon seeds) and a presentation from Richard Pisano Jr., president of Citrus and Allied Essences Ltd, about novel citrus flavors.

Native to the rainforests in Chile and Argentina, Maqui berries are known for its functional benefits including weight loss, detox properties and cardiovascular health. The berries were analyzed with SPME and GC/MS at F&F Projects Ltd., where 300 flavor compounds were identified. Some of the compounds include linalool, hexanol, ethyl butyrate, ethyl acetate and ethyl alcohol, among many others.

Watermelon seeds are sought out for its high protein, energy-boosting properties, digestive support and cholesterol benefits. The seeds contain approximately 60 flavor compounds and an additional 100 when roasted. More research needs to be done to improve flavors that might be lost in drying, baking and freezing.

From superfood to citrus flavors, Pisano discussed unique citrus flavors like mandarin, blood orange and yuzu during his presentation, “Novel Citrus Varieties, Their Individual Flavor Profiles and Uses.” Starting with an Italian mandarin oil of the Tardivo di Ciaculli variety, the oil imparts juicy flavor characteristics and some fishy notes to flavor formulations. Popular in European markets, blood orange has only begun to appear in U.S. markets. The Tarocco variety of blood orange, which was sampled, is the most flavorful type of blood oranges with a sulfury, green profile. Lastly, he highlighted a yuzu oil, which is produced in Japan and provides pine and papaya characteristics to formulations.

“For most citrus species, there are many varieties, hundreds of varieties. Not all of them [have] essential oils produced,” said Pissano. “Essential oils need to be commercially viable and there has to be a significant pool of fruits to make it worthwhile.”

Beets, Beverages, Breakthroughs

Ilana Orlofsky’s presentation, “The Most Disruptive Beverages You Should Know About,” highlighted popular ingredients in beverages and popular flavor trends.

Starting with water, she spotlighted how energy waters, tree waters, caffeinated and protein-fortified waters are all pushing the boundaries of what was previously accepted in the category. From there, she highlighted several ingredients that have made their way into all kinds of beverages, including matcha, CBDs, MCT oils and apple cider vinaigrette. The overall trend of these products and ingredients is tapping into the consumers’ desire for products that address flavor innovation, well-being and health concerns.

Taking a forecast of flavor trends to come, Orlofsky said, “Definitely, [we are] going to be seeing less traditional fruits, more exotics fruits and less conventional vegetables …Beets, in particular, is one that we are watching and is starting to proliferate...and we’ve seen in both in food and beverage.”

Solving Solubility

In “Solubility and Flavor Performance,” Cindy Cosmos, principal flavor chemist for Bell Flavors & Fragrances, highlights issues surrounding solubility and how to address them.

“We can make a great flavor. It can smell great and taste great. Then, we watch it fall apart,” said Cosmos. “Have your flavors ever been blamed for this … ‘Why does my beverage have a white ring at the top, these gummies have no flavor after two weeks, the flavor isn’t staying in my marinade or dressing.’ Flavors can be blamed for just about anything, in any product. We are the culprit. The solution can be summed up in one word: solubility.”

A flavor is comprised of a solute (the flavor itself) and a solvent (the carrier) that produces a solution and comes in either liquid compounds or powder chemicals. To create a stable flavor, Cosmos suggests the order of addition be based on the component’s solubility threshold. Additionally, a stress test should be implemented to overcome issues from transportation, as well as considering the packaging and final product appearance.

A Toast to Whisky and Beer Flavors

Capping off day two was a toast to craft beer and whisky flavors with a presentation from Shane McDonald, Ph.D., principal flavor chemist for Kalsec, followed by a presentation from Ewan Morgan, national director for Diageo Reserve Program.

In the “Craft Beer Flavor Infusion” presentation, McDonald gave a primer to the history of craft beer and how its flavors can be used in flavor development. American craft beer got its start in the 1980’s as people became enthused about home brewing, which later became legalized. At that time, brewers only focused on the basic ingredients – water, yeast, hops and malts. Following a period of growth, the craft beer trend of the 1980’s died down before being revitalized in the 1990’s with developers who embraced a variety of unique flavors. Today, craft beer flavors have become so popular that they are spilling over into other categories, including sauces and seasonings, snacks, meat products, cheeses, confections and other. In 2016, 74 products launched with craft beer styles flavors, followed by another 58 in 2017.

Craft beer flavors provide several unique challenges for the flavorist and flavor professional. Hop flavors can be particularly hard to work with, as they often contribute bitterness and can contain off notes. Additionally, just adding hop oil to a flavor formulation is not enough. Other flavor challenges include regulatory considerations (halal and others), beer’s high-water content which generally results in lower flavor concentrations and cost.

The conversation turned from beer to spirits for the final presentation of the day. In Morgan’s “The Formation of Flavor in Whisky,” he gave a history and primer to whisky flavors and its production. The first known reference to Scotch whisky was found in 1494 in the Exchequer Rolls of Scotland, where friar John Cor was tasked to create whisky for James IV. In the late 19th century, whisky grew to a global flavor due to the impact of phylloxera insect, which was responsible for destroying most of the vineyards in Europe.

Following a history of whisky, Morgan dived into the Clynelish style of Scotch whisky and provide insight to whisky’s flavor characteristics and how to manipulate them. Single malt whisky production takes barley, corn, rye and wheat and processed through milling, mashing, fermentation, distillation and maturation. At each level, the distiller works to control conditions and manipulate flavor. If you are looking to create a nutty/spicy whiskey flavor, the fermentation time would be around 40-50 hours, while fruity flavors are produced at 100 plus hours. Distillation is also crucial to the flavor development of whisky. When stills are run hot, it provides less copper contact and produces heavier, more sulfury flavors. Similarly, the maturation process of whisky provides other flavor characteristics. With up to three years of maturation, the whisky still has its smoky flavors but over time it dies off and becomes sweeter.

At the end of the presentation, Morgan cheered the crowd at Flavorcon and said, “That is why we are here today. We can control flavors. We can manipulate flavor. We make the world a much better place and we make people smile because we are in charge of these flavors.”

Going Beyond the Clean Trend

“Trends are flowers,” said Kevin Ryan, senior brand strategist and former director of strategy and innovation for General Mills, in his opening keynote presentation on the final day. Ryan went on to explain that like flowers, trends can either blossom and grow or fade and die. What’s most important isn’t the flower but the soil – the foundation that goes into the trend.

“When I think of the clean consumers, I’m not looking at [whether this product] is anti-processed,” said Ryan. “I’m looking at what’s underneath that. How do we start to unpack what’s underneath, so we can understand what’s long-term?”

As a brand strategist, Ryan examines the elements that build the foundation for the clean trend as we know it today. He highlighted five ways to show how clean products are addressing larger consumer’s concerns:

- A respite from modern living. As the world becomes faster and over-stimulated, many consumers are looking for a break from modern living. Clean products resonate with their desire for simpler times and simpler food products.

- Controlling one’s health. One of the biggest appeal to clean consumers is the “health halo” that clean products are better for you. In addition to eating healthy, consumers are actively looking for ways to control their health. Clean products directly address these concerns with health claims and marketing.

- Fear of the unknown. On the flip side of wanting to control their health, consumers also are often scared of unforeseen health risks, regardless of the science. Clean labeled products cut the unforeseen elements from consumer goods.

- Balancing the world of extremes. Similar to a respite from modern living, many consumers are looking to bring balance to their life. Clean labeled products are seen from consumers as a way of restoring balance.

- Make food work harder. In addition to all the perceived benefits of clean labeled products, consumers are looking for their products to do more. Consumers see clean products as providing more benefits and functions for their money.

What’s Sweet in Bioproduction?

Older than the wheel, fermentation is arguably one of the earliest forms of technology. Now, fermentation is opening a new opportunity to the flavor industry as a possible solution to sourcing concerns. To discuss this, Brendon Dusel, automation specialist for Conagen, presented “A Sweet Outlook on Bioproduction of High-Value Targeted Ingredients.”

“Why is it one of the first technologies?” asked Dusel. “Let’s look at the key qualities of fermentation. It is robust. It is relatively cheap technology. It is sustainable. Most importantly, it changes a lot of materials, such as barley and milk, into precious commodities of high value, like beer and cheese. It kind of fulfills the dream of alchemy. It transmutes the everyday, the common, into something special.”

Now in the 21st century, biotechnology is expanding on the idea that fermentation can address raw material availability and sustainable sourcing. Traditional sources for production (harvesting) are often influenced by outside factors, like climate and weather influences, market volatility and challenges with extraction. Dusel argues that biotechnology provides a solution to this, as it is often scalable to meet demand and unaffected by weather conditions or outside influence. Instead of growing the ingredient in a field, fermentation takes a substrate of the desired ingredient and an enzyme to create the ingredient in a vat. Finishing off his presentation, Dusel sampled an example of a bioproduced lactone and RebM.

Healthy Products With Full Flavor

The discussion on ingredients and trends continued with Jonathan Anobile, assistant director of technology transfer for FlavorHealth, and his presentation on creating healthier flavors without compromising taste.

Highlighting the importance of products with low sugar and calories, Anobile said, “Looking globally at regulation and health, there are a lot of regulatory agencies, such as the World Health Organization, [that] have issued guidance on how much sugar that we should be consuming… This has resulted in regulatory bodies issuing sugar taxes, which are popping up domestically and globally. These acts have put pressure on CPGs to put lower sugar on their products by applying a tax on products that have certain sugar levels.”

Anobile discussed methods to create flavors that enhance sweetness, elongate salt tastes and block bitter tastes. When a straight sugar reduction of 50% is done in a beverage or food application, a sweetener like Stevia often has to be added to bring back the flavor and characteristics of the sugar. For salt tastes, Anobile shared his experience with sodium reduction with a major consumer brand. Due to concerns about its impact on the product, they initially reduced the product by 20% sodium with little change to consumer perception. Sodium reduction can be done either as a stand-alone solution and is compatible with yeast extracts, KCI and other sodium reduction tools.

A Look at Indie Distillery

Wrapping up the final day of presentations, Colin Spoelman, co-founder and master distiller at Kings County Distillery, gave a history primer on the American independent distillery market.

While Ewan Morgan’s presentation on day two looked at a Scottish whisky, Spoelman traced the 350-year history of whiskey in the United States. American whiskey has seen a resurgence in recent years due to the interest in artisanal batches and production. In 1980, there were only 13 distillers and today, approximately 1,600. However, 1,600 of the distilleries in operation today produce less than 1% of spirits sold, which are largely small batch and craft products.

Following the history of American distilling, Spoelman highlighted the hallmarks of a quality craft whiskey. Whiskey consumers and distillers are both interested in ingredient sourcing and the distilling process. Local ingredients and the return of pot stills and distillation-focused spirits have become hallmarks of independent distilleries. On the finished product side, whiskeys that are bonded (which follow strict aging laws) and whiskey with unique flavors, like quinoa, mesquite, IPA and chocolate, are becoming more popular.

Looking to the future of whiskey and how trends influence the beverage, Spoelman said, “One of the difficult things about making whiskey is you are not really able to follow trends with the speed of other food products. You have to anticipate things four to eight to 12 years out. There is comfort in knowing that whiskey rarely changes very much, and so 12-year-old whiskey will be popular today and in the future.”

Tech Flavors and Lab Safety at the Innovation Stage

In addition to a robust conference schedule and expo hall, Flavorcon 2018 premiered its Innovation Stage, which featured bite-sized presentation on a range of flavor-related issues and topics. On day one, Jesse Coiro, director of business development and sales operation for Erlab, presented on how to create a safe lab environment through the use of odor elimination. Highlighting Erlab’s HALO technology, Coiro showed how proper ventilation can provide a lab with safety and annual energy savings of $5,000 per hood.

The conversation then turned to an interactive kind of technology with a presentation by Nimesha Ranasinghe, Ph.D., assistant professor for the school of computing and information science at University of Maine. During his “Augmented and Virtual Flavors” presentation, he demonstrated his “Vocktail” device, which created flavors through electrical stimulation, digitally controlled smell emission and color sensations. Using the idea that taste and flavor are multisensory sensations, devices like this and others can be used to create accessible flavors.

FMPs, Authenticating Vanillin and Masking Plant Proteins

Day two featured discussions on ingredients on the Innovation Stage. Starting the series of presentations was Scott Chaplin of SCMC Consulting who discussed the multi-functional ingredient trehalose. Naturally occurring in seaweed, shrimp, honey, yeasts and mushrooms, this multi-functional ingredient can be used to retain freshness and enhance flavors. Additionally, the ingredient can be used to overcome negative off-notes in proteins, minerals and high-intensity sweeteners while protecting the flavor quality during processing.

Following this presentation, Corinne Duffy, technical marketing manager for Solvay, presented “Authentication of a Flavoring Substance: The Vanillin Case.” First produced in 1894, vanillin has become a popular ingredient in many food and beverage products and can be derived from natural and synthetic sources. As natural demand continues to rise, authentication of natural vanillin is key in sourcing and production. One way to determine the natural authentication of vanillin is from 14C activity analysis. A vanillin that is created from fossil fuels (synthetics) will be depleted of its 14C, while natural vanillins and synthetic vanillins from lignin will contain the carbon structure marking its naturality.

Mark Hines, R&D director for Magnasweet/ Mafco Worldwide explored flavoring for plant proteins in “Glycyrrhizic Acid Derivatives for Effective Plant Protein Masking.” As more consumers opt for products with plant proteins, the need to mask bitter protein flavors is increasing. Extracted from licorice root, monoammoniated glycyrrhizinate provides a delayed sweetness and extended linger. Additionally, it can be used to effectively mask green, cardboard, and grainy off flavors of pea protein isolate.

The Future of Flavorcon

Next year’s event will take place November 11-12, 2019 at the Duke Energy Convention Center in Cincinnati, Ohio. Registration and event details to follow. To stay up-to-date on Flavorcon 2019, make sure to subscribe to Perfumer & Flavorist’s e-newsletter.

“Flavorcon 2018 was a tremendous success,” said Deniz Ataman, Perfumer & Flavorist managing editor and Flavorcon conference director. “We’ve expanded our conference to include more food and beverage manufacturers to bring the flavor value chain closer together. And we introduced a dynamic experiential exhibit hall for everyone to meet, talk and taste face-to-face. We look forward to hosting the flavor industry in Cincinnati next year.”